This article was co-authored by Howard Fleischmann. Howard Fleischmann is an Automotive Tire and Repair Specialist and the CEO of Community Tire Pros & Auto Repair, with ten locations throughout Phoenix, Glendale, Yuma, and Casa Grande, Arizona. Howard specializes in full-service auto repair and tire replacement and care for domestic/imported vehicles and large trucks. Howard’s dedication to Community Tire Pros & Auto Repair has earned their team multiple awards and features including the 2021 Phoenix Magazine AZ State 48 “Best of the Best!”, the 2020 “Best of Phoenix” in Auto Repair, the 2013 Master SBD award, the 2013 National “Top Shop” award by Tire Review, the 2012 Diversity Champions Phx Business Journal, the 2009 BBB Ethics award, the 2008 Phx Chamber of Commerce Impact Award -” Small Business of the Year”, and the 2008 ASU Spirit of Enterprise award. Howard is often referred to as “The Car Guy” for local TV stations and is a regular on TV’s Channel 3 Sunday, Good Morning Arizona monthly.

This article has been viewed 490,057 times.

Replacing drum brakes isn't difficult but it requires special tools and a little caution. In return, you save on hefty auto mechanics bills. This article will describe the general process, but you will still want to consult the manual for your car's particular make and model.

Steps

-

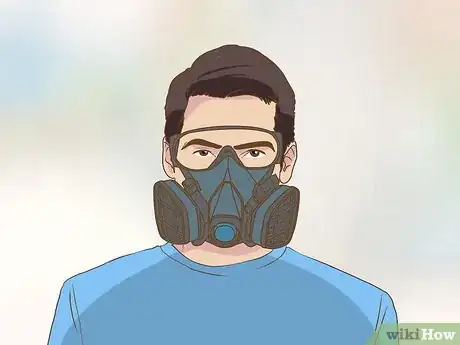

1Put on an asbestos respirator. The work you're about to do involves finely-ground brake dust or asbestos dust, and breathing it can be extremely hazardous to your health. Get a mask that's designed for the job of filtering asbestos, not a simple paper one you might use in a shop. Send the kids and pets away, too. Especially the kids—you don't want them anywhere near this project, not even for a moment.[1]

-

2Remove the hubcap and loosen the lug nuts. Block the front wheels with wheel chocks. Jack up the car and support it with jack stands.

- Never work on a car supported by a jack alone. Blocks of wood or bricks or even cinder blocks aren't suitable substitutes.[2]

- Finish removing the nuts and remove the tire.

Advertisement -

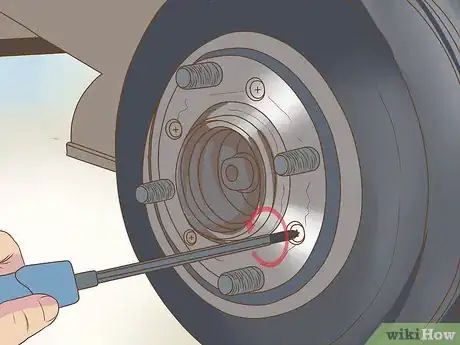

3Spray the hub of the wheel with a penetrating oil such as PB Blaster.[3]

- Note: WD-40 is not a penetrating oil.

-

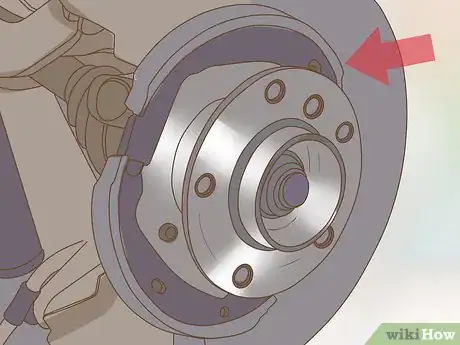

4Grab the brake drum by the edges and pull it off. It may help to wiggle it a bit as you pull. It may be necessary to back off the brake adjuster to remove the drum. This is done through the brake adjustment hole in the drum or on the backing plate using a brake adjuster tool to turn the adjuster to loosen the brakes enough to remove the drum.[4]

-

5Note: some brake drums are held on with screws so you will need to remove those first.

-

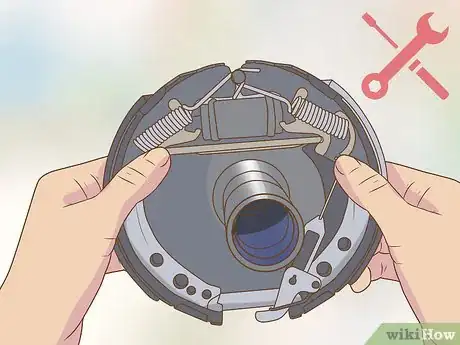

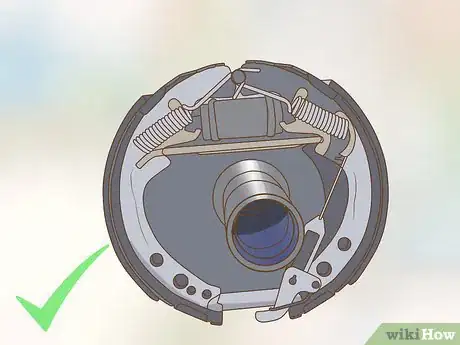

6Once the drum is off take a look at it.

- It should be refaced or replaced if it is scored.

- Drum brakes have a bunch of springs and levers for the self-adjuster and parking brake. They are usually different colors. Take a picture with a digital camera or make a detailed drawing of where everything is before you take anything apart!

-

7Place the whole brake mechanism in a container and spray it with brake cleaner. Doing this in a container will help keep the dust from becoming airborne. Remember: the dust from most brakes is asbestos, and you don't want to breathe it in. Wear a mask.[5]

-

8Compare the new brake shoes with the old ones. Make sure they have holes in all the same places. Some vehicles have two different shoes called a leading and trailing shoe.

- Make sure the brake shoes are the same width.

-

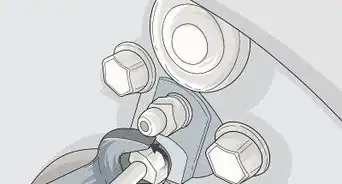

9Dismantle the brake.[6]

- Remove the shoe return springs.

- Detach the parking brake lever.

- Hold the shoe retaining pin from the back and remove the retainer springs.

- Spread the shoes apart from the top and disengage the shoes from the wheel cylinder pins.

- Remove both shoes and the self-adjuster as one unit.

- Lay the old shoes on the ground next to the new ones.

- Sometimes the front and back shoes are different. The shoe with the shorter strip of lining usually goes towards the front.

- Carefully tip the tops of the shoes inward to loosen the tension on the self-adjuster spring.

- Remove the self adjuster.

- Inspect and clean all brake parts to be reused and check for signs of damage or wear and replace as needed.

- It is recommended to replace all the springs with a new set.

- The adjuster should be unscrewed, cleaned and lubed with anti-seize.

- Remove the spring and immediately hook it onto the new shoes exactly as you removed it.

- Inspect the brake wheel cylinder for any signs of leakage and replace if needed.

-

10Rebuild the new brake.[7]

- The brake backing plates should be cleaned and lubed with a small amount of anti-seize on the slide points and anchor points.

- Screw the self adjuster back in. One side will be a left-hand thread.

- Place the self adjuster on the new shoes and spread the tops apart to tighten the spring.

- Put the shoes back in place and slip the retaining pins through the right holes.

- Install the shoe retainer springs.

- Attach the shoes to the wheel cylinder pins.

- Reattach the parking brake lever.

- Install the return springs.

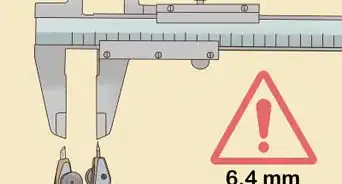

- Using a brake adjustment sizing tool, adjust the brakes to fit the brake drum.

-

11Check your new brakes with the photo you took earlier. If anything looks different start over.

-

12Put it all back together.[8]

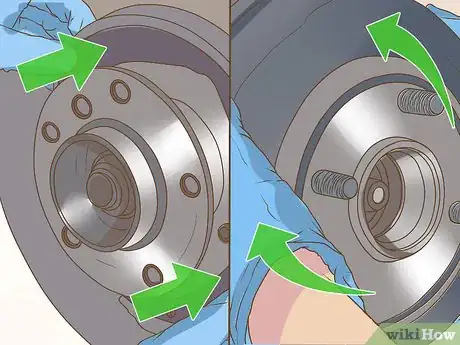

- Slide the new or resurfaced drum over the wheel studs.

- Install lock screws in drum if equipped.

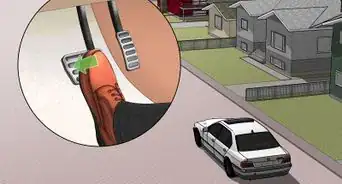

- Adjust the brakes through the drum or through the backing plate till a slight drag on the brake drum is felt.

- Reinstall the tire.

- Check brake adjustment and readjust as needed to have a slight drag on the drum. Do not over tighten the brakes or they could lock up.

- Remove the jack stand.

- Lower the jack.

- Torque the lug nuts and reinstall the hub cap.

- Repeat on other side.

- Bleed out the brake system if any wheel cylinders were replaced.

- Road test the vehicle to verify brakes work correctly.

Community Q&A

-

QuestionWe have bled the brake system, but the pedal still fades. What is wrong?

Community AnswerIf it bleeds off while you are stopped, you probably need a new or rebuilt master cylinder.

Community AnswerIf it bleeds off while you are stopped, you probably need a new or rebuilt master cylinder. -

QuestionDoes it matter which side the longer brake is on?

Tomcat709Community AnswerYes, it does! Most of the thrust to stop happens on the rear of the hub. Put the larger on the rear and the back-up pad (smaller) on the front for secure stopping.

Tomcat709Community AnswerYes, it does! Most of the thrust to stop happens on the rear of the hub. Put the larger on the rear and the back-up pad (smaller) on the front for secure stopping. -

QuestionHow many times do I need to bleed the each side and how do I know when there is no more air?

Community AnswerBleed the brakes utntil the fluid runs clear and you see no more air bubbles. Do this with your engine off.

Community AnswerBleed the brakes utntil the fluid runs clear and you see no more air bubbles. Do this with your engine off.

Warnings

- When the brake drum is removed do not touch the brake pedal. You will pop a piston out of the wheel cylinder and fixing that is a different topic.⧼thumbs_response⧽

- Never work on a car supported only by a jack. Never, not even in an emergency.⧼thumbs_response⧽

- Buy the right tools. They make them for a reason.⧼thumbs_response⧽

- Don't do your own brake repairs if you don't know what you are doing. This is no place to start with auto repairs.⧼thumbs_response⧽

- Avoid breathing brake dust! A particle mask won't help much—asbestos particles are way too small for a simple mask.[9]⧼thumbs_response⧽

Things You'll Need

- A jack

- Jack stand

- Wheel chocks

- Lug wrench

- Various common hand tools. Pliers, screwdrivers etc.

- Brake cleaning spray (2 cans)

- Return spring tool

- Retaining spring tool

- Digital or Polaroid camera

- Repair manual for your vehicle

- Torque wrench

- Dust respirator

- Large container

References

- ↑ https://www.epa.gov/asbestos/current-best-practices-preventing-asbestos-exposure-among-brake-and-clutch-repair-workers-1

- ↑ https://www.popularmechanics.com/cars/how-to/a3663/4283377/

- ↑ https://www.howacarworks.com/brakes/replacing-a-drum-brake-wheel-cylinder

- ↑ https://www.2carpros.com/articles/how-to-replace-rear-brake-shoes-and-drums

- ↑ http://www.health.gov.au/internet/publications/publishing.nsf/Content/asbestos-toc~asbestos-key-handle

- ↑ https://www.howacarworks.com/brakes/replacing-a-drum-brake-wheel-cylinder

- ↑ https://www.youtube.com/watch?time_continue=1&v=Q5j3sKgNoEs

- ↑ https://www.youtube.com/watch?time_continue=1&v=Q5j3sKgNoEs

- ↑ http://www.health.gov.au/internet/publications/publishing.nsf/Content/asbestos-toc~asbestos-key-handle

About This Article

When you’re ready to replace your drum brakes, remove your hubcap and loosen the lug nuts to get started. Then, spray the hub with a penetrating oil like PB Blaster and pull the drum off. Place the whole drum in a container and spray it with brake cleaner. Next, compare the old and new brake shoes to make sure they have holes in all the same places, then dismantle the brake and rebuild it with the new shoes. Keep reading to learn the specific order to disassemble the brake in!