This article was co-authored by Deanna Ranlett. Deanna Ranlett is a Pottery and Ceramics Professional and the Owner of Mudfire Inc. in Decatur, Georgia. With more than 22 years of experience in the ceramics industry and eight years of experience owning a studio, they specialize in glaze formulation, firing ceramic and pottery pieces, general clay projects, and screen printing for ceramics. Deanna holds a BFA in Ceramic Arts and Ceramics from Georgia State University.

There are 8 references cited in this article, which can be found at the bottom of the page.

This article has been viewed 141,920 times.

Pottery is a subset under the broader category of ceramics, and it's commonly used for everyday life, like eating and drinking. Pottery and ceramics in general can often be repaired using the same methods. So, the next time your favorite piece of pottery gets cracked or chipped, don't even consider throwing it out! Instead, try fixing it first. A 2-part epoxy adhesive can work wonders and repair broken pieces of pottery so that they look almost-new once again, and you can fill chips with an epoxy filler.[1]

Steps

Using a 2-Part Epoxy

-

1Fill a 1 gallon (3.8 L) bucket with sand to use as a holder. This won't be necessary for all repairs, but it can be really helpful for items that need to be fixed while held at an angle. Nestle the broken pottery piece into the sand so that the cracked section is facing up. This enables you to use both hands to make the repairs.[2]

- If you don't have sand, you can also use rice to the same effect.

- You could also use a large pot, a shallow serving dish, or something similar to hold the sand as long as it's deep enough to fully support the pottery.

-

2Sand the edges of the chipped area to smooth ragged edges. Use fine sandpaper on both the edges of the broken-off piece and the main piece of pottery. Use a back and forth motion with light pressure until the edges are smooth.[3]

- If you're fixing a crack rather than a full break, you don't need to worry about sanding the piece at this point.

Advertisement -

3Clean the broken pieces with denatured or 91% alcohol and cotton balls. Wipe down the edges both from the main piece of pottery and from the broken-off piece. Let them air dry completely afterwards before moving on to the next step.[4]

- This will ultimately help the adhesive do its job better as there won't be any dirt in the way.

-

4Mix a 2-part epoxy adhesive to fill cracks and reattach broken pieces.[5] Squeeze the epoxy onto a non-porous disposable surface, like a thin sheet of plastic, and use a wooden or plastic stick to mix together the 2 components as quickly as possible. It'll start to harden after 3 to 4 minutes, so you need to work fast.

- Some 2-part epoxies come in a container with a syringe that will distribute both parts equally for you. If yours doesn't come with that, disperse each part of the epoxy in lines so that you can gauge by eye that the 2 components are equal.

- Avoid using superglue for repairs. Superglue is very thin, and while it's strong, it won't protect your pottery from future breakages along the same cracks as well as epoxy will.

Warning: If your piece of pottery is used with food, like a mug or a soup bowl, look for a food-safe adhesive or one that is silicone based.[6] There are both epoxies and other types of adhesives that are FDA-approved for food safety.

-

5Apply the epoxy to each edge of the broken sections. Use the wooden or plastic stick to line the edges of the piece of pottery as well as the cracked piece with epoxy. Don't worry about using too much or if it is going over the edges—you'll be able to remove that excess epoxy later on.

- If you're working with a crack rather than a break, use a toothpick to apply the epoxy to the crack. Push the epoxy into the crack as far as you can, then squeeze the piece together so the crack adheres back together.

Tip: Hold small pieces of broken pottery with tweezers while you apply the epoxy to keep your fingers clean.

-

6Press the broken section back into place as firmly as you can. It's totally okay if epoxy squeezes out around the edges. Get it in line as perfectly as you can and hold it in place for about 30 seconds or as long as the epoxy directions instruct.

- If you're worried about getting the adhesive onto your hands, wear a pair of rubber gloves while you work.

- If there is more than one piece to reattach, do one at a time rather than trying to do them all at once.

- If the pieces aren't staying together well because of the position of the pottery, use a small piece of modeling clay to pinch the edges together. It'll come right off once the piece has fully dried.

-

7Scrape away the excess epoxy with a razor after 20 minutes. You can use a razor blade or a sharp, flat-edged knife. Simply run the blade along the surface of the piece of pottery and slice off any sections of raised dried epoxy.

- Most fast-acting epoxies take about 20 minutes to fully set, but always follow the instructions for whatever brand you're using.

-

8Sand over the edges of the cracks to make the surface perfectly smooth. Take 220-grit sandpaper and rub it very lightly over the sealed cracks on your piece of pottery. This will just finish the process so that there are absolutely no bumps or imperfections on your piece.[7]

- To double-check the surface run your thumb over the sealed cracks. The sensitivity in your finger should allow you to easily feel if there are more sections that need to be sanded.

-

9Paint over the repaired cracked lines if desired. You may not want to or need to do this since the epoxy dries clear, but if you think the cracks are too visible, use acrylic paint to cover those lines.[8] Mix your colors carefully to get as close a match to the original color as possible.[9]

- You can also spray an acrylic gloss over the repaired area if the rest of the piece is shiny and you want the crack lines to be less noticeable.

Filling in Chipped Areas

-

1Wipe off dust and grime from the pottery with a swab of alcohol. Use denatured alcohol or 91% alcohol and a cotton ball. Let the item air dry completely before moving on to the next step.[10]

- Don't skip this part even if you can't see any visible grime in the chip. There could be built up oils or residue that you can't see but that could get in the way of the epoxy adhering to the pottery.

-

2Use 2-part epoxy filler to fill in chips in your pottery.[11] You can buy epoxy filler online or at a home improvement store. Most brands come with 2 components: the filler and a hardener that has to be mixed with the filler once it's ready to be used.[12]

- You could also use a polyester filler to the same effect. Polyester filler tends to be a little less expensive than epoxy filler, but the epoxy filler is usually a little easier to handle and takes less time to dry.

-

3Follow the instructions and mix the filler and the hardener. Squeeze out enough filler to completely fill the chip you're repairing. Read the directions to determine how much hardener you need to mix in with the filler so that it'll work properly.[13]

- Work quickly—the hardener will only allow you 4 to 5 minutes to work with the filler before it gets too stiff to be pliable still.

- For the best results, work in a room that is 75 °F (24 °C) or warmer.

-

4Fill the chipped section completely with the prepared filler. Use a wooden or plastic stick to fill the entire chipped area with the filler. If needed, use a toothpick to poke it into small, hard to reach areas. It's okay if the filler isn't even with the rest of the pottery—you'll deal with that part later.

- Even though the filler might resemble putty, don't use your hands to put it in place. Continue using your wooden or plastic stick.

-

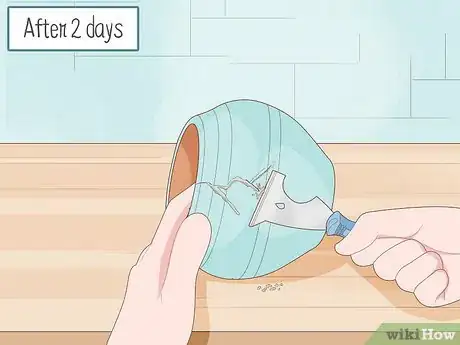

5Shave off the excess filler with a razor once it has hardened. Epoxy filler can take anywhere from 2 hours to 2 days to harden, so make sure to check the manufacturer's instructions for that information. Use a razor or a straight-edged knife to shave off larger chunks of filler that is raised up over the surface of the piece of pottery.

- Don't worry about getting the edges to look perfect with the razor. You'll use sandpaper later on to smooth things out.

-

6Sandpaper the filler-filled area to smooth it down. Take a piece of 220-grit sandpaper and gently rub it back and forth over the repaired area. Keep working at it until the surface is once again completely smooth.

- Once you're done sanding, give the piece another wipe down with alcohol to get rid of any sandpaper and filler residue.

Tip: For sections that have corners or edges, wrap sandpaper around a dowel to give yourself a little more control over the sanding process.

-

7Paint the repaired area with acrylic paint to match the original color. Because the filler is most likely brown or white, you'll probably want to paint it so it doesn't stick out as much from the rest of the piece. Take your time matching the color of the paint to the color of the piece of pottery.[14]

- Try thinning the acrylic paint with a little bit of water so that it can be applied more evenly over the surface.

-

8Finish the piece with a coat of clear spray acrylic to give it a shine. This spray will add a layer of gloss to the repaired area, which will make it stand out from the rest of the piece less. If possible, use the spray outside or in a well-ventilated area so that you aren't bothered by the fumes. Let the gloss completely dry before you use or display the pottery piece again.

- It generally takes acrylic spray about 12 to 24 hours to completely dry. Test it by patting it with your thumb—if it still feels tacky it needs more time.

Expert Q&A

-

QuestionWhat is the best glue for pottery repair?

Deanna RanlettDeanna Ranlett is a Pottery and Ceramics Professional and the Owner of Mudfire Inc. in Decatur, Georgia. With more than 22 years of experience in the ceramics industry and eight years of experience owning a studio, they specialize in glaze formulation, firing ceramic and pottery pieces, general clay projects, and screen printing for ceramics. Deanna holds a BFA in Ceramic Arts and Ceramics from Georgia State University.

Deanna RanlettDeanna Ranlett is a Pottery and Ceramics Professional and the Owner of Mudfire Inc. in Decatur, Georgia. With more than 22 years of experience in the ceramics industry and eight years of experience owning a studio, they specialize in glaze formulation, firing ceramic and pottery pieces, general clay projects, and screen printing for ceramics. Deanna holds a BFA in Ceramic Arts and Ceramics from Georgia State University.

Pottery & Ceramics Professional Two-part epoxies are one of the best options out there! If the item is a decorative ceramic piece, you could also use a super glue to repair it.

Two-part epoxies are one of the best options out there! If the item is a decorative ceramic piece, you could also use a super glue to repair it. -

QuestionHow can I fix a crack in pottery?

Natasha Dikareva, MFANatasha Dikareva is a San Francisco, California based sculptor, and installation artist. With over 25 years of ceramics, sculpting, and installation experience, Natasha also teaches a ceramic sculpture workshop titled "Adventures in Clay" covering concept development, hand-building techniques, texture, and glazing techniques. Her work has been featured in solo and group exhibitions at the Beatrice Wood Center for the Arts, Abrams Claghorn Gallery, Bloomington Center for the Arts, Maria Kravetz Gallery, and the American Museum of Ceramic Art. She has taught at the University of Minnesota and the American Indian OIC School. She has been awarded the Excellence Award at the 1st World Teapot Competition, Best in Show at the 4th Clay & Glass Biennial Competition, and a Grand Prize at the American Museum of Ceramic Art. Natasha holds an MFA from the University of Minnesota and a BFA from Kiev Fine Arts College.

Natasha Dikareva, MFANatasha Dikareva is a San Francisco, California based sculptor, and installation artist. With over 25 years of ceramics, sculpting, and installation experience, Natasha also teaches a ceramic sculpture workshop titled "Adventures in Clay" covering concept development, hand-building techniques, texture, and glazing techniques. Her work has been featured in solo and group exhibitions at the Beatrice Wood Center for the Arts, Abrams Claghorn Gallery, Bloomington Center for the Arts, Maria Kravetz Gallery, and the American Museum of Ceramic Art. She has taught at the University of Minnesota and the American Indian OIC School. She has been awarded the Excellence Award at the 1st World Teapot Competition, Best in Show at the 4th Clay & Glass Biennial Competition, and a Grand Prize at the American Museum of Ceramic Art. Natasha holds an MFA from the University of Minnesota and a BFA from Kiev Fine Arts College.

Ceramics & Sculpting Instructor There are different ways to fix a crack in pottery. You can make the crack bigger and then fill it with a mixture of the same clay and some particles of fire clay. Buy magic water to fix cracks in sculptures or use vinegar to repair them.

There are different ways to fix a crack in pottery. You can make the crack bigger and then fill it with a mixture of the same clay and some particles of fire clay. Buy magic water to fix cracks in sculptures or use vinegar to repair them. -

QuestionWhat are the different types of clay?

Natasha Dikareva, MFANatasha Dikareva is a San Francisco, California based sculptor, and installation artist. With over 25 years of ceramics, sculpting, and installation experience, Natasha also teaches a ceramic sculpture workshop titled "Adventures in Clay" covering concept development, hand-building techniques, texture, and glazing techniques. Her work has been featured in solo and group exhibitions at the Beatrice Wood Center for the Arts, Abrams Claghorn Gallery, Bloomington Center for the Arts, Maria Kravetz Gallery, and the American Museum of Ceramic Art. She has taught at the University of Minnesota and the American Indian OIC School. She has been awarded the Excellence Award at the 1st World Teapot Competition, Best in Show at the 4th Clay & Glass Biennial Competition, and a Grand Prize at the American Museum of Ceramic Art. Natasha holds an MFA from the University of Minnesota and a BFA from Kiev Fine Arts College.

Natasha Dikareva, MFANatasha Dikareva is a San Francisco, California based sculptor, and installation artist. With over 25 years of ceramics, sculpting, and installation experience, Natasha also teaches a ceramic sculpture workshop titled "Adventures in Clay" covering concept development, hand-building techniques, texture, and glazing techniques. Her work has been featured in solo and group exhibitions at the Beatrice Wood Center for the Arts, Abrams Claghorn Gallery, Bloomington Center for the Arts, Maria Kravetz Gallery, and the American Museum of Ceramic Art. She has taught at the University of Minnesota and the American Indian OIC School. She has been awarded the Excellence Award at the 1st World Teapot Competition, Best in Show at the 4th Clay & Glass Biennial Competition, and a Grand Prize at the American Museum of Ceramic Art. Natasha holds an MFA from the University of Minnesota and a BFA from Kiev Fine Arts College.

Ceramics & Sculpting Instructor There are different types of clay depending on their firing temperature. Earthenware is a low-temperature clay, and mid-range clays are known as stoneware. Porcelain is a high fire range clay.

There are different types of clay depending on their firing temperature. Earthenware is a low-temperature clay, and mid-range clays are known as stoneware. Porcelain is a high fire range clay.

Things You'll Need

Using a 2-Part Epoxy

- Large bucket

- Sand

- 2-part epoxy adhesive

- Plastic or wooden stirrer for epoxy

- Non-porous surface to mix epoxy

- Tweezers (optional)

- Razor or flat-edged knife

- Toothpick

- 220-grit sandpaper

- Acrylic paint

- Paintbrushes

- Denatured or 91% alcohol

- Cotton balls

Filling in Chipped Areas

- 2-part epoxy filler

- Denatured or 91% alcohol

- Cotton balls

- Razor or flat-edged knife

- 220-grit sandpaper

- Acrylic paint

- Paintbrushes

- Clear spray acrylic

References

- ↑ Deanna Ranlett. Pottery & Ceramics Professional. Expert Interview. 12 November 2021.

- ↑ http://www.lakesidepottery.com/Pages/Pottery-tips/How-to-fix-broken-pottery-china-ceramic-lesson-1.htm

- ↑ https://youtu.be/oMyx4PqBLJQ?t=98

- ↑ http://www.lakesidepottery.com/Pages/Pottery-tips/How-to-fix-broken-pottery-china-ceramic-lesson-1.htm

- ↑ Deanna Ranlett. Pottery & Ceramics Professional. Expert Interview. 12 November 2021.

- ↑ Deanna Ranlett. Pottery & Ceramics Professional. Expert Interview. 12 November 2021.

- ↑ https://youtu.be/Rg4q0g8zXi8?t=132

- ↑ Natasha Dikareva, MFA. Ceramics & Sculpting Instructor. Expert Interview. 5 May 2020.

- ↑ http://www.lakesidepottery.com/Pages/Pottery-tips/painting-coloring-repaired-ceramic-sculpture-tutorial.htm

- ↑ http://www.lakesidepottery.com/Pages/Pottery-tips/How-to-repair-chipped-pottery-china-ceramic-step-by-step.htm

- ↑ Deanna Ranlett. Pottery & Ceramics Professional. Expert Interview. 12 November 2021.

- ↑ http://www.lakesidepottery.com/Pages/Pottery-tips/How-to-repair-chipped-pottery-china-ceramic-step-by-step.htm

- ↑ https://youtu.be/Rg4q0g8zXi8?t=95

- ↑ http://www.lakesidepottery.com/Pages/Pottery-tips/painting-coloring-repaired-ceramic-sculpture-tutorial.htm