This article was co-authored by Alberto DeJesus. Alberto DeJesus is a Construction Specialist and the CEO of DeJesus Industries. With more than four years of experience, he specializes in high-end real estate development and construction. Alberto and DeJesus Industries have been featured on NBC News and have worked with numerous well-known companies, including Mazda, Amazon, and CVS. Alberto holds a Bachelor’s degree from Boston University.

This article has been viewed 624,056 times.

Curing is the process of keeping new concrete moist so it develops its maximum strength. Non-cured concrete is susceptible to cracking and collapses, so always cure new concrete. There are 2 main methods of curing. Wet-curing is covering the concrete with a sheet and keeping it soaked with water for 7 days. It's time-consuming, but produces the best results. For a faster method, spray the concrete with a curing compound to lock moisture in and aid the curing process. Whichever method you choose, make sure the weather is warm enough to pour concrete and avoid placing weight on the concrete until the curing process is complete.

Steps

Wet-Curing the Concrete

-

1Wait until the water sheen evaporates from the concrete surface. During the drying process, water bleeds from inside the concrete and settles on top, making a sheen. When this layer evaporates, it indicates that the top layer of concrete is durable enough to resist surface damage. The evaporation process should take about an hour, but monitor the concrete for the right time to begin curing. When the surface water evaporates, then begin the process.[1]

-

2Get a fabric sheet that will cover the entire concrete slab. A fabric sheet traps water and keeps the concrete moist. Fabrics like burlap and cotton are best. Normal sheets are acceptable as well if you don’t have other fabrics. Measure the concrete area to see how much fabric you need, and get a sheet that will cover the whole thing.[2]

- You can also use multiple sheets for larger slabs. As long as the concrete is covered, it doesn't matter how many you use.

- Soak the fabric with clean water before placing it down. This removes any solvents or contaminants that could stain the concrete.

- Find a light-colored fabric if you can, because this reflects the sunlight better than a dark color.

Advertisement -

3Cover the concrete with the fabric. Once the concrete is strong enough, unroll the fabric over the entire surface. Make sure all the concrete is covered, including the edges and sides if the concrete is raised. Stand back and look around the perimeter to make sure no concrete is visible. Cover any areas that are still showing.[3]

- Be careful not to step on the concrete while you do this. It’s still not strong enough to support weight.

-

4Hose the sheet down with water to soak it. Although the sheet may already be wet from when you rinsed it off, re-wet it so As soon as you lay the sheet down, hose it down completely with water. Continue watering until the entire sheet is wet.[4]

- Don't spray so much that water pools on the surface. Just enough to wet the entire sheet will work.

- Using a sprinkler can also work. Place the sprinkler on the center of the concrete if you can reach without stepping on it and let the sprinkler run. If you can’t reach the center of the concrete, place the sprinkler on the edge and angle it inward instead. Leave the sprinkler running until the sheet is completely wet.

-

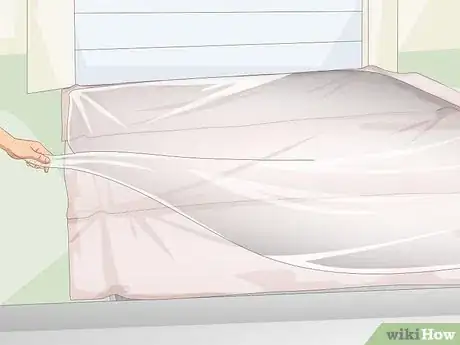

5Spread a plastic sheet over the fabric to lock moisture in. Cover all the fabric and don’t let any parts stick out. This covering locks in moisture and helps the curing process. Use light or transparent plastic for temperatures above 60 °F (16 °C). Use dark-colored plastic for temperatures below 60 °F (16 °C) to absorb more sunlight. Place buckets or similar heavy objects on each corner of the plastic, beyond the concrete edge, to keep it from blowing away.

- Using a plastic sheet is not a requirement, but it keeps moisture in more efficiently than the fabric alone. If you don’t have a plastic sheet, take extra care to keep the fabric sheet wet constantly.

-

6Re-wet the fabric sheet every day for 7 days. Monitor the sheet and re-wet it any time it’s drying out. Peel off the plastic, spray the fabric down, then replace the plastic to keep the moisture in. Recheck the fabric multiple times per day for 7 straight days.[5]

- If you’re not using a plastic sheet, the fabric may need rewetting as many as 10 times a day, depending on the temperature. Check the fabric as often as you can and wet it whenever it’s drying out.[6]

-

7Remove the covering after 7 days. Keeping the concrete constantly wet for 7 days completes the wet-curing process. Once that time passes, peel off the plastic and fabric to finish the job.

- Remember that at this point, the concrete is still not strong enough to support heavy weights. If the concrete is in your driveway, wait another week before driving your car on it.

Applying a Curing Compound

-

1Select a curing compound based on the needs of your project. If you don’t want to continuously monitor and re-wet the concrete, a curing compound locks the moisture in without the need for constant re-wetting. Visit a hardware store and look for a curing compound. There are several types available, so compare products and find one that is best for your need.[7]

- Compounds are usually transparent or light-colored. Transparent ones don’t show on the concrete, but a colored one reflects the sunlight better. Use a colored one for hot, sunny climates.

- Some compounds dissolve on their own and others need to be scrubbed off. Check the product packaging to determine which type you have.

- If you plan on painting the concrete, use a compound that is non-reactive with paint.

- If you don’t know which product is best for you, consult a store employee for guidance.

-

2Wait until the water sheen evaporates before applying the compound. When concrete dries, water bleeds from inside it and settles on the surface, causing a sheen. When this evaporates, the top layer is solid enough to resist damage. Applying the compound before the water evaporates causes it to soak into the concrete and leave the surface uncovered. Wait about an hour for the surface water to evaporate so the sheen disappears. At this point, the concrete is ready for curing.

-

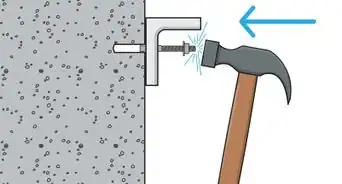

3Spray or brush an even layer of compound on the concrete surface. Some curing compounds come in a spray bottle, and others come in a bucket and have to be brushed on with a paint roller. Whichever type you have, apply an even coat of compound across the entire concrete surface. Don’t forget about the sides and edges.[8]

- Normal compound coats cover an area of 150–200 sq ft (14–19 m2) per 1 US gal (3.8 l), but always check the product for recommended coat thickness.

- Don’t let the compound pool in any spots. Keep the sprayer or roller moving to spread it evenly.

- If you’re using a spray applicator, stop to pump it as soon as the stream weakens to maintain even coverage.

- If you're using a sprayer, wear goggles to prevent any from getting in your eye.

- Don’t press down hard with the roller. The concrete isn’t strong enough to handle pressure yet.

-

4Leave the compound undisturbed for 7 days. After spraying the compound on, leave it to do its work. It seals the concrete and locks moisture in for the curing process. After 7 days, the curing process is usually complete.[9]

- Different products may have different application times. Always follow the directions given on the product you use.

-

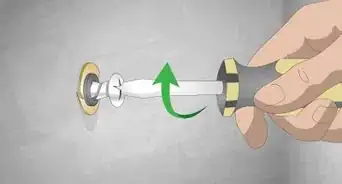

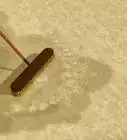

5Scrub the compound off if it doesn’t disintegrate on its own. Some curing compounds don’t disintegrate and need to be removed. Put on goggles and gloves to protect yourself. Then, use a steel-bristle brush to scrub off all the compound. Work across the entire concrete surface to remove everything. Then spray the concrete down with a hose to push off any remnants of the compound.[10]

- Some steel-bristle brushes connect to buffing machines, making the job much easier. Buy or rent one with this feature to complete the job faster.

- Always double check the instructions on your compound packaging to confirm the correct removal method.

Providing the Right Conditions

-

1Pour concrete when the temperature will be above 50 °F (10 °C) for at least 7 days. Concrete cures best in temperatures above 50 °F (10 °C), so check the forecast for the next week. If you can expect warm temperatures, then now is the right time to pour the concrete.[11]

- Pouring in the spring or summer is ideal to avoid any unexpected cold weather.

- If there is a sudden cold snap after pouring the concrete, professionals usually protect the concrete by building a structure around the site and using a portable heater. This is an expensive option, but it’s the best choice to protect the concrete.

-

2Wait 24 hours to walk on the concrete. While the concrete is curing, it can’t handle excessive weight. Let it dry for a full 24 hours before stepping on it to prevent damage to the surface.[12]

- If you’re water-curing the concrete, take extra care to avoid stepping on it while you re-wet the fabric.

- If the concrete is in an area with a lot of foot traffic, block the area off and hang signs warning about wet cement. Make sure any pedestrians will know they can't step on the area.

-

3Drive on the concrete only after 10 days have passed. Even if the concrete looks dry, it can't handle excessive weight until after it cures completely. If the concrete is in your driveway or a similar area that cars drive on, wait at least 10 days before driving or parking your car on it.[13]

- If you have a large vehicle like an RV or truck, wait 28 days before parking it on the concrete.

- Also wait 28 days if this is a commercial area with a lot of vehicle traffic, like a parking lot. The weight from multiple vehicles can cause the concrete to sink.

-

4Let the concrete harden for a full month before painting or staining it. Introducing new chemicals to the concrete before it’s completely hardened can interfere with the curing process. Wait a full month before applying any paints or stains to the concrete.[14]

- If you do want to paint the concrete and used a curing compound, remember to get one that is nonreactive with paint.

Expert Q&A

-

QuestionWhat is the best weather for concrete to cure?

Alberto DeJesusAlberto DeJesus is a Construction Specialist and the CEO of DeJesus Industries. With more than four years of experience, he specializes in high-end real estate development and construction. Alberto and DeJesus Industries have been featured on NBC News and have worked with numerous well-known companies, including Mazda, Amazon, and CVS. Alberto holds a Bachelor’s degree from Boston University.

Alberto DeJesusAlberto DeJesus is a Construction Specialist and the CEO of DeJesus Industries. With more than four years of experience, he specializes in high-end real estate development and construction. Alberto and DeJesus Industries have been featured on NBC News and have worked with numerous well-known companies, including Mazda, Amazon, and CVS. Alberto holds a Bachelor’s degree from Boston University.

Construction Specialist Around 50°F (10°C) is a good temperature for curing concrete. Just make sure that it hasn't rained recently or heavily around the time of your project.

Around 50°F (10°C) is a good temperature for curing concrete. Just make sure that it hasn't rained recently or heavily around the time of your project. -

QuestionHow long before I can put back cabinets on the new garage floor?

Community AnswerDepends on the mix, but usually 24 hours. You may want to water cure the slab for a few days. If this is the case, you should wait until finished water curing.

Community AnswerDepends on the mix, but usually 24 hours. You may want to water cure the slab for a few days. If this is the case, you should wait until finished water curing. -

QuestionWhich concrete mix uses the greatest amount of cement per cubic yard?

Community AnswerIn today's world, concrete is sold in units of psi. For example: Most places require at least 2000 psi concrete for such things as footers, and slabs (like floors) will be at least 3000 psi. Basically, the higher the psi, the more cement is used. A local concrete company in your area can expertly guide you for the proper mix for your project.

Community AnswerIn today's world, concrete is sold in units of psi. For example: Most places require at least 2000 psi concrete for such things as footers, and slabs (like floors) will be at least 3000 psi. Basically, the higher the psi, the more cement is used. A local concrete company in your area can expertly guide you for the proper mix for your project.

Things You'll Need

Wet-Curing the Concrete

- Hose

- Water

- Fabric sheets

- Plastic sheets

Applying a Curing Compound

- Goggles

- Curing compound

- Hose

- Paint roller

- Steel-bristle brush

Warnings

- While you can get away with not curing concrete that only supports foot traffic, always cure concrete that will see vehicle traffic. Vehicle weight can collapse uncured concrete.⧼thumbs_response⧽

- If you're unsure of your ability to lay and cure concrete, talk to a professional contractor to do the job.⧼thumbs_response⧽

References

- ↑ https://www.cement.org/learn/concrete-technology/concrete-construction/curing-in-construction

- ↑ http://www.ce.memphis.edu/1101/notes/concrete/PCA_manual/Chap12.pdf

- ↑ http://www.ce.memphis.edu/1101/notes/concrete/PCA_manual/Chap12.pdf

- ↑ http://www.ce.memphis.edu/1101/notes/concrete/PCA_manual/Chap12.pdf

- ↑ https://www.cement.org/learn/concrete-technology/concrete-construction/curing-in-construction

- ↑ https://www.bobvila.com/articles/curing-concrete/

- ↑ https://www.bobvila.com/articles/curing-concrete/

- ↑ http://www.ce.memphis.edu/1101/notes/concrete/PCA_manual/Chap12.pdf

- ↑ https://precast.org/2011/07/to-cure-or-not-to-cure/

- ↑ https://www.concreteconstruction.net/how-to/removing-curing-compound_o

- ↑ Alberto DeJesus. Construction Specialist. Expert Interview. 15 December 2021.

- ↑ https://www.bobvila.com/articles/curing-concrete/

- ↑ https://www.bobvila.com/articles/curing-concrete/

- ↑ https://www.bobvila.com/articles/curing-concrete/

About This Article

After you’ve laid concrete, you’ll need to cure it so it retains its maximum strength. One way to cure concrete is with a wet fabric sheet like burlap or cotton. You’ll need to lay the sheet on top of the concrete as soon as the water sheen evaporates from its surface. Spread a plastic sheet on top of the fabric to lock the moisture in. Then, keep adding water whenever it gets dry so the fabric stays wet for 7 days. Alternatively, you can lay a curing compound on top of the concrete. This will come in a spray bottle or bucket that you’ll need to spray or brush on. Apply it in an even layer and leave it for 7 days to cure. If it doesn’t disintegrate by then, scrub it off with a steel brush. For more tips, including when to paint or stain new concrete, read on!