wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 9 people, some anonymous, worked to edit and improve it over time.

wikiHow marks an article as reader-approved once it receives enough positive feedback. In this case, 92% of readers who voted found the article helpful, earning it our reader-approved status.

This article has been viewed 237,842 times.

Learn more...

Buying vintage stereo equipment is a hobby that can quickly turn into an obsessive and overwhelming collection. The look, feel, and tone of vintage audio components have a unique charm, and these components often rival much more expensive, newer models in their quality. Unfortunately, old and neglected components are often found in pretty rough shape, which means you'll need to learn how to clean vintage stereo equipment before use. The steps below will walk you through cleaning the interior of any audio component using a basic contact cleaner.

Steps

Picking a Cleaner

-

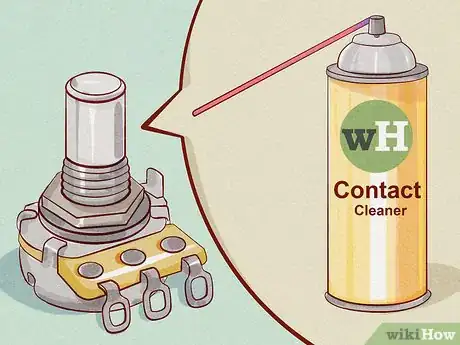

1Purchase a bottle of contact cleaner which is labeled as "safe to use on plastics." This is extremely important. Contact cleaner is a spray or liquid product that is designed to dissolve corrosion on metal electronic parts, typically the main cause of scratchy and popping sounds while moving volume controls or intermittent rotary or push-button switches (for speaker selections, modes, source) headphone or microphone jacks, etc. While all contact cleaners work on metal-only parts, most will actually destroy plastics and safe lubricants found inside and outside of almost every volume control potentiometer and switch.

- Choosing a contact cleaner which will restore and not harm your equipment is always a better choice than using a low-cost contact cleaner, as replacing your original part once the hidden internal plastics cracked or melted, or the metal shaft seized, are often impossible and tedious at best, so you are better to not attempt to clean with a questionable product and instead live with the unit as it is until you can obtain a suitable contact cleaner which will not harm your precious treasure. You can usually purchase a safe bottle at a decent electronics store or over the internet though it is important to be certain shipping of the product is approved by the shipping service as many contact cleaners are flammable and sometimes cannot be shipped certain methods or to certain locations.

-

2Look for a brand that offers quick-drying, no-residue application, as you won't be able to wipe many of the internal components dry. CAIG DeoxIt is a popular brand of contact cleaner and they have "D5" specifically for cleaning vintage stereo equipment correctly without harming the plastic components. They are an industry leader in contact cleaners for audiophiles and offer product support and product suggestions for specific applications. "D5" is an industry standard in the broadcast world and safely removes oxidation from the metals while avoiding harm to the internal plastic pieces and lubricants that most audio potentiometers contain.Advertisement

-

3Avoid using products on your classic stereo equipment that are not intended for use on plastics in your stereo. Avoid WD-40 (a renowned metal contact cleaner not always necessarily safe on all plastic parts) as it is not intended for use on most pieces that contain or touch plastic parts or have lubricants required to be able to turn. Testing before use may not be your option so use the online forums for advice first before trying something not reversible, you can save some headaches and heartaches.

-

4Read and understand all labels on your contact cleaner and if you have any doubts, don't use it. Damage cannot be undone. Equipment damaged or destroyed by contact cleaners which are not safe on plastics can sometimes end up on the internet (where you can't try before you buy) with no reference to seized or cracked controls so be careful to ask sellers if the knobs still turn or slide freely without excessive force or have shaft or neck breakage hidden by glued knobs etc. You can typically buy a few basic models of low-cost modern reproduction volume controls over the internet and test different contact cleaners on them to see what works and what doesn't before risking your stereo equipment's rare original pieces.

Cleaning the Equipment

-

1Unplug your stereo equipment. To make sure that no electricity will be flowing through the internal components while you clean, unplug the audio equipment. Do not simply turn the power switch off; remove the plug entirely from the wall outlet as death could otherwise occur. Please note that a qualified technician should be at hand, and while many are unable to choose contact cleaners wisely, many can help you avoid a shock from a charged capacitor which can at least shock or burn your hand from skin to conductor contact even while the unit say unplugged for a long time. Be careful and look-up electrolytic capacitors for information.

-

2Remove the cover of the stereo component. The case of the component is usually removed by loosening a few small screws or bolts. Often these screws will be located on the sides, back, and bottom of the unit. Not all screws on a given surface are for the casing so look carefully at what you are unscrewing so as to only remove the casing screws. After removing them, set them aside or put them into numbered containers in order to match them up with the correct holes you can put stickers on afterwards, taking pictures can help too, and gently lift the case away from the chassis.

-

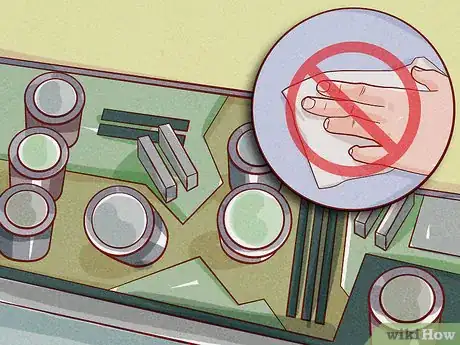

3Spray compressed air throughout the unit's interior if needed. If the interior components look particularly dusty, you can clear away the dust using a spray can of compressed air. Do not attempt to wipe dust away using a cloth, as a clumsy hand can easily dislodge or damage delicate electronic components, or scratch a shiny plastic faceplate.

-

4Spray contact cleaner on parts to be cleaned sparingly. Contact cleaner can be used to remove corrosion or stubborn dirt from many of the stereo component's internal parts, but typically you will want to clean contacts that cause problems beyond looks. Spray a fine, even coat of the contact cleaner on any component that is believed to be problematic due to oxidation, applying a thicker coat in areas that display significant corrosion. Spray jacks, plugs, any switches or removable connectors that are not soldered, and certainly battery contacts if any as these cause the most problems and may even require additional friction to clean or replacement if eaten away by alkaline battery acid.

- The contact cleaner may air dry in a few hours; no wiping is typically necessary, but... avoid spray on things you don't want affected that should not be sprayed, such as rubberized belts, friction wheels, pulleys, motor shafts, meter displays, light bulbs, audio or video heads, window or dial faces. Good luck cleaning any of those off if they get a mist on them. Be certain to not soak high voltage power switches as they may at some point ignite so please don't flood your high voltage power switches with contact cleaners, they almost never need to be cleaned and are safer to replace if they would.

-

5Clean the potentiometers with contact cleaner. The pots, or knobs, are the components most likely to display corrosion. To clean them, find the small hole in the back assembly of the pot or typically larger opening where the pins are soldered to the board. Spray sparingly an amount of contact cleaner into the hole or into the openings of which there are typically two separate openings for stereo potentiometers, and then work the knobs back and forth frequently for about a minute. This will spread the contact cleaner throughout the inside of the pot.

-

6Clean the faders and buttons as you did the pots. To clean faders and push buttons, you'll have to sometimes spray the contact cleaner behind the controls from the front of the unit if access is impossible from the inside without major disassembly. After spraying the cleaner, push the button or slide the fader back and forth for about a minute. Any excess cleaner that drips down the faceplate of the unit can be wiped away with a microfiber scratch-resistant cloth.

-

7Allow the unit to air out for several hours. After applying contact cleaner to any part of your vintage stereo equipment, let the unit sit with the case off for a few hours. This helps ensure that all the contact cleaner has dried.

-

8Replace the component's case. Replace the case gently, and secure it using the screws or bolts you removed, screwed back together first by fingertip, then by screwdriver. Be certain to not force or over tighten as this can strip the threading and certainly crack any plastics easily. Remember the force required to undue the screws in the first place? Only after the case is back in place should you plug the audio equipment back in and test it. Any extra screws should mean rechecking your assembly because every screw is there for a reason otherwise manufacturers would save parts and time if it was not absolutely needed for safety or sturdiness. Good luck!

Community Q&A

-

QuestionWhat is the best chemical to clean the metal faceplate on my Pioneer RT-909?

Community AnswerFirst remove the knobs, then the faceplate. Lay faceplate flat on old towel and spray with diluted glass cleaner (two parts cleaner to one part water), let it sit for two minutes until the grime is dissolved and wipe it off with a clean, damp rag. Rinse the rag thoroughly with clean water and wipe down the faceplate again to remove any glass cleaner residue. Wipe it dry using clean, soft rag or towel, and then reassemble.

Community AnswerFirst remove the knobs, then the faceplate. Lay faceplate flat on old towel and spray with diluted glass cleaner (two parts cleaner to one part water), let it sit for two minutes until the grime is dissolved and wipe it off with a clean, damp rag. Rinse the rag thoroughly with clean water and wipe down the faceplate again to remove any glass cleaner residue. Wipe it dry using clean, soft rag or towel, and then reassemble. -

QuestionI have a Kenwood KR 4140 stereo receiver that has been sitting on a shelf for 20 years. What should I do if it isn't working?

Community AnswerTake the cover off (10-12 screws). Get a can of compressed air, blow dust and cobwebs off each board (from one side to the other so as to not blow dust one way, then back the other way). Now inspect each capacitor (hard wired batteries) for acid leakage. If there is any, remove the capacitor, clean up the acid with a cotton swab and rubbing alcohol, and replace the capacitor. Next, look at solder points on everything (I know, tedious, but you don't want a short!), you want to make sure each transistor, resistor, and capacitor wire is secure. Also, look to see that solder is only touching one trace per wire, or you could have a short. If everything looks okay, assemble, plug in, and turn it on (assuming it's not wet from alcohol). Repeat if necessary.

Community AnswerTake the cover off (10-12 screws). Get a can of compressed air, blow dust and cobwebs off each board (from one side to the other so as to not blow dust one way, then back the other way). Now inspect each capacitor (hard wired batteries) for acid leakage. If there is any, remove the capacitor, clean up the acid with a cotton swab and rubbing alcohol, and replace the capacitor. Next, look at solder points on everything (I know, tedious, but you don't want a short!), you want to make sure each transistor, resistor, and capacitor wire is secure. Also, look to see that solder is only touching one trace per wire, or you could have a short. If everything looks okay, assemble, plug in, and turn it on (assuming it's not wet from alcohol). Repeat if necessary. -

QuestionHow do I get the knobs off my vintage stereo equipment?

Community AnswerUse two old soup spoons, one on each side of the knob, and place the bottom of the spoon against the face plate. Use the spoons to gently pry off the knobs. The bottom of the spoon will act as a pivot and lever. Push the handles toward the face plate to remove the knob. This will not scratch the knobs or the face plate, and makes the removal safe and easy.

Community AnswerUse two old soup spoons, one on each side of the knob, and place the bottom of the spoon against the face plate. Use the spoons to gently pry off the knobs. The bottom of the spoon will act as a pivot and lever. Push the handles toward the face plate to remove the knob. This will not scratch the knobs or the face plate, and makes the removal safe and easy.

Warnings

- The instructions above should only be used for cleaning transistor-based equipment, not vacuum tube-based equipment. Vacuum tubes can hold a lethal electrical charge for months after being unplugged, and should be serviced by professionals only.⧼thumbs_response⧽

- Contact cleaner is highly flammable, and so should not be used near open flames, lit cigarettes, or extreme heat sources.⧼thumbs_response⧽

Things You'll Need

- Stereo equipment

- Screwdriver

- Compressed air

- Contact cleaner

- Cloth

- All-purpose cleaner