This article was co-authored by Jerry Ehrenwald. Jerry Ehrenwald, GG, ASA, is a graduate gemologist in New York City. He is the previous President of the International Gemological Institute and the inventor of U.S.-patented Laserscribe℠, a means of laser inscribing onto a diamond a unique indicia, such as a DIN (Diamond Identification Number). He is a senior member of the American Society of Appraisers (ASA) and is a member of the Twenty-Four Karat Club of the City of New York, a social club limited to 200 of the most accomplished individuals in the jewelry business.

wikiHow marks an article as reader-approved once it receives enough positive feedback. In this case, 90% of readers who voted found the article helpful, earning it our reader-approved status.

This article has been viewed 142,802 times.

Silver jewelry is a great alternative to gold jewelry. It is cheaper, but still sturdy and visually appealing. But, silver jewelry needs care and keeping just like any other precious metal, and is just as likely to need repairs at some point. Repairing and cleaning silver jewelry is a bit more difficult than dealing with gold, so it will take a bit more care and possibly the help of a jeweler.

Steps

Repairing Broken Clasps

-

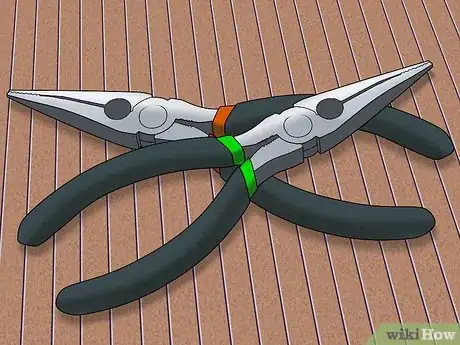

1Get two pairs of flat nose pliers. You can buy these for relatively cheap at your local hardware store. You can also purchase a jewelry repair kit from a hobby store, which will come with special pliers and tools needed for repair. Just make sure you get a pair of flat nose pliers that are small enough to handle smaller pieces of jewelry.[1]

- If you’re buying the pliers on their own rather than as part of a kit, you’ll need two pairs in order to hold each end of the broken clasp.

-

2Purchase a new clasp, and extra jump rings. Since your clasp is broken, you’ll need to buy a new one to attach on your jewelry. Get a silver plated clasp and a few jump rings, or connector rings, in order to secure the clasp to your jewelry. You can buy these supplies online, or you can find them at a local hobby or crafting store.[2]

- You can buy clasps and jump rings in all different kinds of material. They’ll most likely be plated in silver rather than made from silver.

Advertisement -

3Open the jump rings and remove the old clasp. Using the flat nose pliers, grip the ring connecting the clasp to the chain or string. There should be a slit in the ring where it does not fully connect; grip it on either side of this slit. Pull one hand towards you and push one hand away, separating the two sides. Slide off the old clasp.[3]

- Make sure you don’t pull the jump ring outward. This will only bend the ring and make it very difficult to get it back into its normal shape.

-

4Add the new jump rings and clasp. Remove any jump rings that may be damaged or broken and replace them. Then, on the last jump ring, hook the new clasp on before closing the ring. Make sure the jump rings are closed and secure.[4]

- If you’re having trouble seeing the clasp and jump rings, consider purchasing a hands-free magnifying glass. This will help you see what you’re doing but still keep your hands free to work.

Using a Soldering Torch

-

1Use a hard silver solder. You want to make sure you purchase a hard solder and not a soft solder. A soft solder will not work with silver jewelry, and may actually damage it further. You can purchase hard silver solder online, or from a local hardware store.[5]

- You can choose to buy solder wire, or sheets. The sheets are generally cheaper, and will allow you to cut the size you need.

-

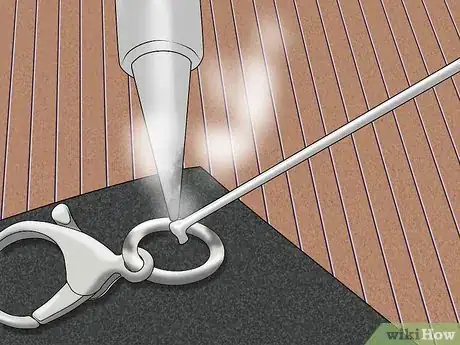

2Use a soldering torch. Soft solder can be soldered with a soldering iron, which is electric. Hard solder must be soldered with a torch, with is powered by gas. Butane torches are useful for standard jewelry repair jobs like fixing jump rings and reattaching small chains.[6]

- Always handle soldering torches carefully. Wear protective gloves and make sure you are in a room with good ventilation to avoid inhaling any fumes.

-

3Use flux when soldering. Flux cleans the metal prior to soldering so that it can bond and melt properly. Use a liquid flux to coat the surface you’re soldering before beginning. You can also purchase flux sprays made specifically for hard soldering, and for working with silver.

- Hard soldering might also require pickling after being soldered, in order to clean it. You can purchase separate pickling liquid, or you can even use a flux that is self-pickling.

- Brush flux onto the joint or surface you plan to solder before applying the solder.

-

4Use the torch to solder the silver pieces. If you are soldering two pieces together, for example, place the solder wire against the spot you need to solder. Adjust the torch to its highest temperature setting, and heat the wire until it melts. Once it melts, it will join with the silver piece you’re repairing or bonding with another piece.

- After soldering, you will want to rinse the newly repaired or joined piece in water, then pickle it to clean it if the flux you used wasn’t self-pickling.

Seeking Help From a Jeweler

-

1Take your silver jewelry to a jeweler if you need it resized. Resizing silver jewelry is much more difficult and time consuming than resizing gold. When melting down the silver to resize it, it gets very dirty through oxidization. A jeweler will be able to make sure the piece returns to its previous shiny state after resizing.

- Keep in mind that if you have a silver ring with a stone in it, some jewelers may tell you it can’t be resized without taking the whole ring apart. Silver conducts heat through the entire ring, making it difficult to resize when there is a stone setting on the piece.

-

2Consider that silver jewelry repair may take longer and cost more than gold. Even though the silver itself is less valuable per ounce compared to gold, it is time consuming to repair. A jeweler might price the work at a high rate simply because of how long it is going to take them to repair the piece and then polish it back to its normal coloring.

-

3Look for a jeweler who has a laser welding machine. Laser welding is the safest way to resize and work on silver, as it won’t harm the metal the way traditional torch welding will. Laser welding will allow a jeweler to resize a silver ring with a stone on it, for example, when the same couldn’t be done with traditional torch welding.[7]

- A laser welding machine can cost upwards of $20,000, so smaller, independent jewelers might be less likely to own or have access to one.

Dealing With Tarnish and Scratches

-

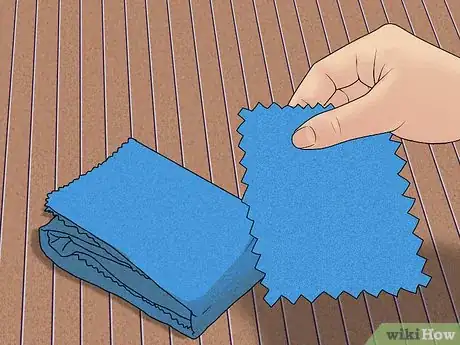

1Use a special silver polishing cloth. These cloths are made specifically for cleaning and polishing silver. They don’t require any liquid cleaner or polishing agent. Just use the cloth to gently buff away tarnish and restore the jewelry to its natural shine.[8]

-

2Avoid using dips and polishing agents. Liquid polishing agents and dips are harsh chemicals that could damage plated silver. They need to be used in very well-ventilated areas, as well, as the smell could be hazardous to your health. You also may have to dispose of these chemicals carefully, as they are considered hazardous.[9]

- These heavy-duty cleaners can also cause your jewelry to tarnish more quickly, as they could strip the protective surface off.

-

3Use a homemade silver cleaner. If the polishing cloth doesn’t do the trick, you can try using things from your kitchen to clean your silver jewelry. A little bit of phosphate-free dishwashing soap and warm water, for example, could help.[10] Or, try using a paste made from baking soda and water. Apply a small dollop (about the size of a pea) to your jewelry and use it to buff away tarnish.[11]

- Always rinse your jewelry after using any kind of polish, homemade or otherwise. Rinse it briefly, then dry it with a clean cloth. You don’t want any polish to get stuck on the jewelry anywhere and harden.

-

4Be careful when cleaning silver jewelry that contains precious gemstones. Certain gemstones may require special attention when cleaning. If your silver jewelry contains fragile pieces like pearl, you will want to make sure you only use cleaning or polishing agents that are safe for these parts of the jewelry.[12]

-

5Repair shallow scratches by buffing with regular toothpaste. Put a little bit of toothpaste on a cloth. After wetting down the piece of silver jewelry, rub the toothpaste gently into it using circular motions. Rinse the jewelry again. If the scratch is still there, repeat the process. If the scratch doesn’t go away after a few tries, it may need to be taken to a jeweler for repair.

- Don’t use toothpaste that is for tartar control or has a whitening agent. These ingredients are too abrasive and may actually end up damaging the silver.

References

- ↑ http://www.realsimple.com/beauty-fashion/diy-beauty-treatments-fashion-fixes/repair-broken-jewelry-clasp

- ↑ http://www.realsimple.com/beauty-fashion/diy-beauty-treatments-fashion-fixes/repair-broken-jewelry-clasp

- ↑ http://www.realsimple.com/beauty-fashion/diy-beauty-treatments-fashion-fixes/repair-broken-jewelry-clasp

- ↑ http://www.realsimple.com/beauty-fashion/diy-beauty-treatments-fashion-fixes/repair-broken-jewelry-clasp

- ↑ http://www.rings-things.com/Learn/Soldering-101/

- ↑ http://www.rings-things.com/Learn/Soldering-101/

- ↑ http://www.rofin.com/m/laser-tools/jewelry-collection/time-to-buy-a-laser-welder.html

- ↑ https://www.youtube.com/watch?v=Qc02oY1Gk04

- ↑ http://blog.novica.com/how-to-clean-and-care-for-sterling-silver-jewelry/

- ↑ Jerry Ehrenwald. Former President, International Gemological Institute & Graduate Gemologist. Expert Interview. 12 August 2019.

- ↑ http://blog.novica.com/how-to-clean-and-care-for-sterling-silver-jewelry/

- ↑ http://blog.novica.com/how-to-clean-and-care-for-sterling-silver-jewelry/