This article was co-authored by Pete Sveen. Pete Sveen is a DIY enthusiast based in Montana. He creates and shares inspiring video tutorials on building projects, from furniture construction to metalworking. His YouTube channel, DIY Pete, has over 240,000 subscribers.

This article has been viewed 52,712 times.

A cutting board provides a sturdy cutting surface that will keep you from damaging your counters when cutting fruits, vegetables or other food. You can buy a cutting board in a home furnishings store, but you can make your own with a few supplies. This tutorial is for a butcher's block with alternating strips of wood, like this one.

Steps

Collecting Your Supplies

-

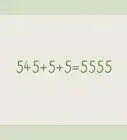

1Buy three thick planks of wood to build your board. You can use any wood you want, in any dimensions, but you should have at least 1" thickness. For this tutorial, you will be using:

- 1 Walnut board 4″ x 20″ x 1″

- 1 Maple Board 4″ x 20″ x 1″

- 1 Cherry Board 4″ x 20″ x 1″[1]

-

2Round up your construction and safety supplies. This is a simple tutorial, but it does require a fair amount of supplies to do correctly. You should have:

- Wood glue

- Safety gloves, goggles, and earmuffs

- Tape measure

- Pencil

- Earmuffs

- 2-3 sets of clamps.

Advertisement -

3Ensure you have the correct woodworking machines. You will need to be comfortable with the following machinery and know how to use it safely.

- Orbital sander

- Table saw

- Miter saw

- Planer

-

4Measure and cut your board to 1/2 or so longer than your final length. The final length of the board comes down to you -- this tutorial will be aiming for a 12" x 16" board. No matter your final length, leave an extra 1/2 or so now -- you'll clean the edge to your exact specifications later.

- No matter what your length, make sure you cut all the boards to the same length.

- You can use either the miter saw or the table saw.

- Make sure you cut off any rough edges.

Composing the Board

-

1Mark the "width" of each strip in your cutting board with a pencil. Again, the exact width is up to you, but 3/4" is a good, workable thickness. Measure out each strip of wood on the walnut, maple, and cherry boards with your pencil.

- You want the strips to run lengthwise along each board -- you'll then alternate strips from each type of wood to build the final cutting board.

-

2Use the table saw to cut each strip of wood. Working slowly, cut along your pencil lines. You should end up with three sets of perfectly even strips of wood. They look like square posts.

- The number of strips you end up with will depend on the starting width of your wood.

- You can play with or adapt this formula -- cutting different widths to get a variable striping on your final board -- if you want.

-

3Line up all of the strips of wood, placing them in the pattern you like. The easiest style is to alternate -- cherry, maple, walnut, cherry, maple, walnut, cherry... etc. Rotate the strips so that the nicest side is facing up, and place the wood into a "dry cut" of the final cutting board.

-

4Rotate each strip clockwise so that the side faces up. You'll be using wood glue to adhere the wood strips to each other, so turn each piece over so that the side you'll be gluing faces upward.

-

5Apply wood glue liberally to each strip of wood. Use your fingers or a brush to apply glue to one side of every strip of wood. You want glue covering the entire side. Don't worry about dripping or excess glue now -- you'll clean it up later.

-

6Press all of the wood evenly together. Rotate the wood back counter-clockwise so that the glue sides are between each piece of wood. Line them up and press them together, making sure they don't buckle or slide.

-

7Attach clamps on either side of the board so that the wood is pressed closed together. This is necessary to help the wood glue dry appropriately. Make sure, as you apply the clamps, that the wood stays level. No pieces should "buckle" or push upwards. Ensure that the bottom or top is roughly even as well.

-

8Lift the clamped set of strips of the work surface, drying the wood glue so that it doesn't stick to the table. Lift the cutting board vertical and let it dry for the recommended time on the wood glue bottle.

- This should take 1-3 hours, but check the bottle for specifics.

Finishing and Polishing the Board

-

1Remove the clamps and use a chisel to remove large chunks of glue. Take the clamps off once the wood glue dries. If there are any big chunks of glue on the board, lightly chisel them off now.

-

2Run the board through your planer. This gives it an even, perfect surface. You don't need to take much off -- only a few millimeters. Run both sides through for a perfectly smooth board.

- Taking off roughly a 1/8 on an inch from each side will generally get out any issues or imperfections.[2]

-

3Use your table saw or miter saw to cut your edges to perfect size. Now that all the strips are attached it is easy to get the board to the perfect size. Set your saw to your final length, here 16", and cut the ends of the board to your final length.

-

4Use your orbital sander to give the board a smooth polish. After the planer, you shouldn't need to do a lot of sanding. Use 220 grit paper to smooth the board, round the edges, and take out any roughness created by the saw.

-

5Finish the board with some food-grade mineral oil. This puts a protective coating on the board and makes it easier to clean and work with. Use a damp rag to wipe off the board, then dry it thoroughly. Working in small circles, apply the food-grade mineral oil to the board, using a rag to apply a thin coating across the entire board. Let it dry and your cutting board is ready to use.

- The final board should have a light shine on it. Reapply the mineral oil if it seems rough, woody, or unfinished in places.

- Linseed oil and beeswax are two common food-grade oils.

Community Q&A

Did you know you can get answers researched by wikiHow Staff?

Unlock staff-researched answers by supporting wikiHow

-

QuestionWhy is wood so commonly used for chopping boards?

wikiHow Staff EditorThis answer was written by one of our trained team of researchers who validated it for accuracy and comprehensiveness.

wikiHow Staff EditorThis answer was written by one of our trained team of researchers who validated it for accuracy and comprehensiveness.

Staff Answer wikiHow Staff EditorStaff Answer

wikiHow Staff EditorStaff Answer -

QuestionWhat is a silicone cutting board?

wikiHow Staff EditorThis answer was written by one of our trained team of researchers who validated it for accuracy and comprehensiveness.

wikiHow Staff EditorThis answer was written by one of our trained team of researchers who validated it for accuracy and comprehensiveness.

Staff Answer wikiHow Staff EditorStaff AnswerThis is a lightweight cutting board made from silicone; it is very slim (like a credit card) and it can be rolled up into a cone or cylinder after chopping for easy transfer of the cut ingredients into a pan or bowl. Some silicone cutting boards have images or are colored to help you remember which one to use for fish, meat, vegetables and dairy––useful for religious and households with different dietary needs.

wikiHow Staff EditorStaff AnswerThis is a lightweight cutting board made from silicone; it is very slim (like a credit card) and it can be rolled up into a cone or cylinder after chopping for easy transfer of the cut ingredients into a pan or bowl. Some silicone cutting boards have images or are colored to help you remember which one to use for fish, meat, vegetables and dairy––useful for religious and households with different dietary needs. -

QuestionWhat's the maintenance?

Community AnswerUnless it says dishwasher safe, hand wash after use. Use a food grade mineral oil or board wax on it, following the instructions provided on the bottle. The oil conditions the board so it doesn't dry out, and board wax both conditions and seals out a lot of impurities that can get in. Do that once every couple of months. To extend the life, don't place underneath or very close to the stove or vent, as that will dry it out more quickly.

Community AnswerUnless it says dishwasher safe, hand wash after use. Use a food grade mineral oil or board wax on it, following the instructions provided on the bottle. The oil conditions the board so it doesn't dry out, and board wax both conditions and seals out a lot of impurities that can get in. Do that once every couple of months. To extend the life, don't place underneath or very close to the stove or vent, as that will dry it out more quickly.

Things You'll Need

- Surfaced maple board

- Surfaced walnut board

- Surfaced cherry board

- Tape measure

- Pencil

- Combination square

- Circle guide

- Jigsaw or band saw

- Clamps

- Sanding block, random orbit sander or belt

- Clean cloth

- Natural linseed oil

References

About This Article

To make a cutting board, start by cutting your cherry, walnut, and maple boards to the same length. Then, use a pencil to draw strips of your desired width on each board before carefully cutting the strips with a saw. Line up the strips of wood until you get the pattern you like, then apply wood glue to one side of each strip and stick them together. Finish by pressing the strips tightly together and attaching clamps to each side of the board so the glue can dry. Once the board is dry, remove excess glue with a chisel. For advice on planing and sanding your board, keep reading!