This article was co-authored by Patrick Johns and by wikiHow staff writer, Caroline Heiderscheit. Patrick Johns is a Home Improvement Specialist and the Owner of CatchAll Handyman Services. With more than 28 years of experience, he has worked on a variety of home improvement projects, such as carpentry, plumbing, and door and window installations in both commercial and residential properties.

There are 10 references cited in this article, which can be found at the bottom of the page.

This article has been viewed 10,436 times.

PVC pipes are great solutions for leak-proof plumbing. But how can you be sure to connect your pipes correctly? Luckily, we've got you covered. So, whether you want to learn how to apply PVC cement or learn how to glue PVC pipe when wet, pretty soon, you'll be an expert. Read on to learn all of the very best tips for gluing your PVC pipes!

Steps

Measuring, Cutting, and Deburring PVC Pipes

-

1Measure the correct length of PVC pipe and mark it. Find the length of pipe needed for your project, then mark that same length on your new pipe in permanent marker. When you repair pipes, for example, measure the broken pipe’s length using measuring tape. Then, measure and mark this same length on your replacement pipe.[1]

- Remember, you’re placing both ends into fittings with collars, which will hold the PVC pipes' ends firmly in place. So your measurements will equal the length between the collars of your 2 fittings.

-

2Set up a vice, clamp, or guide to assist with cutting PVC pipe. To cut cleanly and safely with a hacksaw, hold your pipe in place with a clamp or vice. If you don’t have one of those available, build your own DIY guide. Simply screw or nail together 2 pieces of scrap wood so that they create a 90-degree angle. Then, set your pipe in their crook.[2]

- Using a guide will also prevent you from cutting into your workstation and causing unintentional scratches and marks.[3]

Advertisement -

3Cut your pipe using a hacksaw or handsaw. Lay your pipe onto your clamp, vice, or guide. Line up the pipe so that your marking hangs just off the end of your guide for easy access. Then, by simultaneously pushing down and moving the tool back and forth, cut or saw your pipe.[4]

- If you have a cable saw, PVC pipe cutter, or electric miter saw handy, these would work as well.

- PVC pipe cutters are made especially for this material and are particularly helpful. They create clean, easy cuts, sometimes without burrs. However, they only cut pipes up to 2 inches (5.1 cm) in thickness.[5]

-

4Deburr your pipe using a utility knife and fine-grit sandpaper. After cutting your pipe, you may notice small, jagged burrs of plastic around your pipe’s rim. To remove these pieces, gently slice the small chunks off of your pipe’s rim using your knife. Once you’ve removed the burrs, sand the inside and outside of the pipe until it feels smooth. To do this, rub your sandpaper on the pipe in small circles.[6]

- You can also use an emery cloth to smooth out your PVC pipe.[7]

- Leave burrs in place, and your PVC pipe may not form a strong connection. Burrs could also cause liquid-flow issues.

Connecting PVC Pipes

-

1Dry fit your pipes. No matter your PVC pipe project, test-run your pipes' formation before applying cement and primer. Arrange and fit all of your pipes together exactly as your project or instructions direct you to. As you go, double check that you cut and measured correctly. If segments are too long (or worse, short!) to fit, cut the pipe or grab a replacement.[8]

- All of your segments should fit snugly into the pipe-fitting collars.

- If you test things out first, you'll know that everything fits together before you glue.

-

2Mark your PVC pipes with permanent marker. With everything in place from your dry fit, mark the exact order and rotations on your pipes. When fastening a long line of multiple pipes, number the pipes from left to right. For elbow pipes, draw a straight line over every adjoining pipe and fitting. To refasten your elbow pipes correctly later on, you can line up your markings.[9]

- Especially when dealing with curves in your plumbing (elbow pipes), this step will be crucial.

- Forget it, and you could refasten your pipes in the wrong direction or start a job that can't be finished.

-

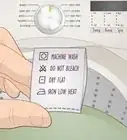

3Purchase PVC-specific cement and primer. How do you use pvc primer and cement? For PVC pipes, read the label carefully. Double check that your cement and primer are made for PVC material. "CPVC," for example, won't glue properly on your pipes. Before buying, check your primer's label to make sure that it's purple in color.

- In most areas, inspectors require that primer be purple. That way, it's clearly visible.

-

4Buy "wet or dry" cement if you'll be working with wet PVC pipes. At home-improvement stores or online, search for special cement if you know you'll be working in wet conditions. Beyond that, the process is the same as with dry pipes.[10]

-

5Coat your pipe with primer before quickly moving on to cementing. Station yourself over something you don’t mind getting dirty (primer and cement stain!). Then, coat your primer 3 times around the outside of the pipe using the primer's built-in brush. Next, run the primer over the inside of the fitting 3 times as well. Apply the primer in a 1 inch (2.5 cm) wide band around the pipe and fitting.[11]

- Before you begin priming, have your cement prepped and ready to go. You have about 10 seconds to apply your cement.

-

6Apply cement to your pipe and fitting. Immediately after adding your primer to your pipe and fitting, apply 3 coats of cement or “glue” onto the outside of your pipe using the cement's built-in brush. Next, apply 3 coats of cement to the inside of your fitting. Apply your cement over the 1 inch (2.5 cm) thick band that you just finished covering with primer.[12]

- Again, move on to the next step immediately. PVC pipe cement will dry in just ~30 seconds. Make sure that your pipe is in place when it does.

-

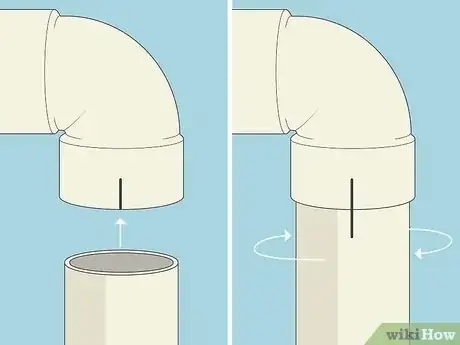

7Push your PVC pipe into its fitting and twist.[13] You want your glue to set when your pipe is properly aligned. So, push your pipe into the fitting a quarter-turn off from the line-markings you made during your dry fit. Then, twist your pipe so that the 2 halves of the line now make a straight line. By twisting the pipe, you’re activating the cement. [14]

- Hold the pipe in place for ~30 seconds. This way, when you turn on your water, you'll know that your pipe set completely and correctly!

Things You’ll Need

- PVC pipe and fittings

- A hack saw, handsaw, cable saw, or PVC pipe cutter

- Primer and cement

- Utility knife

- Sandpaper

- Measuring tape

- Permanent marker

References

- ↑ https://youtu.be/wF6KGbRpewI?t=61

- ↑ https://youtu.be/6MnctTf6ZqM?t=52

- ↑ https://youtu.be/6MnctTf6ZqM?t=52

- ↑ https://youtu.be/SK1EXs8qE3s?t=75

- ↑ https://todayshomeowner.com/the-best-methods-for-cutting-and-gluing-pvc-pipe/

- ↑ https://todayshomeowner.com/the-best-methods-for-cutting-and-gluing-pvc-pipe/2/

- ↑ https://www.wichita.gov/PWU/StormwaterDocuments/Step%20by%20Step%20Instructions%20for%20Removing%20Backflow.pdf

- ↑ https://todayshomeowner.com/video/how-to-align-pvc-pipe-fitting-during-assembly/

- ↑ https://todayshomeowner.com/video/how-to-align-pvc-pipe-fitting-during-assembly/