This article was co-authored by Laura M. Johnson. Laura M. Johnson is a Mural Artist and the Owner of Twin Cities Murals in St. Paul, Minnesota. She has over five years of experience in the industry and has worked professionally across venture capital, communications, the arts, and beyond. She helps empower small and growing businesses to find their voices, share their stories, and grow their impact. Laura received her Master of Business Administration from the University of Minnesota - Carlson School of Management, and her Bachelors in Journalism and Communication Studies with a minor in Fine Arts from the University of Oregon.

There are 12 references cited in this article, which can be found at the bottom of the page.

This article has been viewed 29,354 times.

Much of the appeal of softwoods like pine lie in their beautiful grain, which often includes knots and other attractive natural features. Too many knots, however, can take away from the presentation of a given surface. Some knots can even bleed oils and resins through multiple coats of paint, spoiling the appearance of the finished piece with unsightly discoloration. Fortunately, covering unwanted pine wood knots is an easy fix. Just build up the area inside the knot with a thin layer of epoxy, then seal it with 1-2 coats of stain-blocking latex before applying your paint or stain of choice as usual. We'll walk you through the whole process step-by-step below so you can cover pine wood knots and get the type of finish you're looking for.

Steps

Filling the Knot

-

1Dry oozing knots in freshly-cut pine with a heat gun. Inspect the surface of the wood closely to look for knots that are still releasing resin. If you find any, hold a heat gun 6–8 inches (15–20 cm) away from the spot and wave it back and forth for 20-30 seconds. The hot air will cause the sticky fluid to harden rapidly, allowing it to be sanded away with ease.[1]

- A hair dryer set to the highest heat setting may also help dry up flowing resin if you don’t have a heat gun handy.

- You have the best chance of encountering oozing knots in pieces of wood that have been cut within a matter of days.

-

2Expose knots in pre-painted or stained pine to get them ready for filling. If you’ve got a knot bleeding through a surface that’s already been finished, start by sanding the discolored spot with a sheet of 120-grit sandpaper until the knot itself is visible. Scuffing up the existing paint or stain will create a grippier base surface, helping your filler materials stick and set up better.[2]

- While you’re at it, be sure to remove any loose wood chunks or splinters you find in the area surrounding the knot. A pair of tweezers can come in handy for this.

- Simply slapping an extra layer of paint or stain onto a bleeding pine knot won’t cut it. The natural oils and resins in softwoods are so potent and persistent that they can leach through multiple coats of finish.[3]

Advertisement -

3Prepare a package of wood epoxy according to the directions on the label. Most epoxies just need a good stir and they’re ready to go. Others may require you to mix multiple components, such as a resin and a hardener. Always follow the specific instructions listed on the packaging of the product you’re working with.[4]

- You can pick up a container of epoxy from any hardware store or home improvement center for around $3-5.

- Make sure the epoxy you buy is specifically formulated for use on wood surfaces.

-

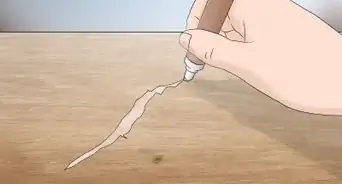

4Spread enough epoxy into the knot to fill it completely. If your epoxy came in a tube, simply squeeze it into the knot until the thick fluid is level with the top. If you got the kind that you have to mix yourself, scoop a small amount into the knot with the tip of a putty knife or hand trowel, then use the flat part of the blade to smooth it until it's fat.[5]

- Wipe off any epoxy that finds its way onto the wood around the knot using an old rag saturated with acetone.[6]

- If you don’t own a putty knife or trowel, a wooden paint stirrer stick or tongue depressor can make an acceptable substitute. Some epoxies come with their own applicator tools, which generally work well for applying and smoothing the product.

-

5Allow the epoxy to cure for 24-48 hours. The built-up finish needs to have a chance to dry and harden before you can paint or stain it. This could take anywhere from 60 minutes to hours, depending on the exact type and amount of the product you’re using. However, it’s best to let the filler sit for a few days to make sure that it’s hard enough to prevent accidental damage during the next phase of your project.[7]

- Check the specifications on the label of the product you’re using for more information on drying times and other guidelines that you may need to know.[8]

- Keep in mind that the temperature and humidity of your work area could have an impact on how long it takes your epoxy to set up. Fluctuations in temperature and moisture tend to slow down the curing process.

Tip: Use a heat lamp, heat gun, space heater, or similar tool to accelerate the curing process. Most epoxies reach their full hardness faster when exposed to mild, continuous heat.[9]

-

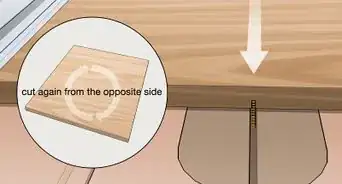

6Sand the epoxied surface smooth with a belt or orbital sander. Once the filled knot has time to cure completely, go over it with your sander to blend the spot into the surrounding wood. Use fluid, circular motions to buff the new finish to a uniform height without leaving scratches or grooves in the soft pine.[10]

- After sanding, wipe the surface with a damp cloth to clear away dust, then wait for it to dry before moving on.

- Progressing from a medium-grit sandpaper to a high-grit sandpaper (somewhere in the range of 120-grit to 400-grit) tends to provide the best results for delicate wood finishing tasks.

Priming the Knot and Finishing the Wood

-

1Brush the filled knot with a stain-blocking latex primer. Dip a small, soft-bristle paintbrush into the primer and glide the bristles over the outer surface of the dried wood epoxy. Make your strokes from several different directions to ensure for full coverage—the primer needs to make contact with each part of the filled knot in order to seal it effectively.[11]

- A basic white or off-white primer will provide the optimal depth of color for your chosen shade of paint.

- If possible, use a brush that’s roughly the same size as the knot you’re covering to avoid over-applying the primer.

Tip: If you plan on staining the surface rather than painting it, use a clear shellac-based clear coat or knotting solution rather than pigmented primer. Both of these products are useful for stabilizing resinous woods like pine.

-

2Let the primer dry for 1-2 hours. Most latex primers are formulated to dry to the touch within a couple of hours. In the meantime, hold off on touch-testing or otherwise handling the surface. Doing so could cause the primer to smear or rub off, ruining all your hard work.[12]

- Running the air conditioning or switching on a ceiling fan or portable box fan in your work space can help speed things up a bit.

-

3Apply 1-2 follow-up coats of primer. Between the epoxy and your initial coat of primer, clear coat or knotting agent, it may not be strictly necessary to give the surface any further treatment. Even so, it’s a good idea to brush on an extra coat or 2 to be absolutely certain that bleeding won’t be an issue. This is especially true if your base coat was relatively thin.[13]

- A good rule of thumb when working with knotty woods is to continue applying thin coats of primer until you can no longer see the knot you’re trying to conceal.

- Another advantage of using epoxy is that it will prevent the knot from absorbing primer, meaning it will disappear from sight much faster.

-

4Give your primer or sealant around 24 hours to cure prior to painting or staining. When you’re satisfied with the coverage and thickness of your primer, allow it to harden to its finished texture. One full day of dry time should be enough to confirm that it’s sufficiently dry.

- As you did when letting your initial coat dry, leave the surface to sit undisturbed to avoid interfering with the primer’s ability to cure properly.

-

5Paint the wood with at least 2 coats of high-quality paint. Now all you have to do is finish painting the surface as usual. For best results, brush or roll on a minimum of 2 coats in your preferred color, making your strokes both with and against the grain for optimal coverage. Afterwards, there will be nothing to indicate that there was ever a knot there in the first place.[14]

- Stick with a latex- or oil-based paint. These will do a better job of sealing the underlying wood than water-based paints, offering an additional layer of protection against bleeding.[15]

- You’re free to apply your primary color using a roller, brush, or sprayer. Select the tool that enables you to work most efficiently given the exact size, dimensions, and style of your piece.

-

6Stain your piece if you'd prefer to preserve its natural finish. First, spread a thin, even layer of polyurethane sealant onto the pine using a lint-free cloth. Then, sand the entire surface with a sheet of high-grit sandpaper to scuff the sealant and prepare it to hold the stain. Finally, use a separate cloth or sponge brush to smooth on one or more coats of gel-based stain in your preferred color. Wipe the surface with an old rag after each application to remove excess stain, and allow each coat to dry for 5-8 hours prior to applying the next one.[16]

- Remember to use a knotting solution or shellac-based clear coat to seal the knots. Pigmented primer will show right through the stain, even if you use multiple coats.

- Apply as many coats of stain as it takes to achieve your desired depth of color. It's not unusual for woodworking and home improvement aficionados to use as many as 4 or 5 layered coats.

- Staining can be a good alternative to painting if you want to showcase the unique grain patterns in the pine surface.

Things You’ll Need

- Medium- or high-grit sandpaper

- Wood epoxy

- Putty knife or hand trowel

- Old rag

- Belt or orbital sander

- Damp cloth

- Stain-blocking latex primer

- Soft-bristle paintbrush

- Latex- or oil-based paint

- Heat gun or hair dryer (optional)

- Tweezers (optional)

- Wooden paint stirrer stick or tongue depressor (optional)

- Acetone (optional)

- Heat lamp, heat gun, space heater, or similar tool (optional)

- Shellac-based clear coat or knotting solution (optional)

- Air conditioning, ceiling fan, or box fan (optional)

References

- ↑ https://sawsonskates.com/how-to-stop-knots-from-bleeding-through-paint/

- ↑ https://baileylineroad.com/brown-stains-coming-through-paint/

- ↑ https://sawsonskates.com/how-to-stop-knots-from-bleeding-through-paint/

- ↑ https://www.prettyhandygirl.com/how-to-fill-voids-and-knot-holes-in-wood/

- ↑ https://www.finehomebuilding.com/2015/01/07/filling-knot-holes-in-flooring

- ↑ https://www.bobvila.com/articles/how-to-remove-epoxy/

- ↑ https://www.oldhouseonline.com/repairs-and-how-to/epoxies-wood-repair

- ↑ https://www.loghelp.com/images/LiquidWood-WoodEpox-Instructions.pdf

- ↑ https://www.assemblymag.com/articles/92850-cure-epoxies-with-heat

- ↑ https://www.youtube.com/watch?v=m8Vck1QKMfA&feature=youtu.be&t=472

- ↑ https://sawsonskates.com/how-to-stop-knots-from-bleeding-through-paint/

- ↑ https://www.paintspraypro.com/how-long-does-it-take-primer-to-dry/

- ↑ https://sawsonskates.com/how-to-stop-knots-from-bleeding-through-paint/

- ↑ https://sawsonskates.com/how-to-stop-knots-from-bleeding-through-paint/

- ↑ https://baileylineroad.com/brown-stains-coming-through-paint/

- ↑ https://extremehowto.com/how-to-finish-pine-furniture/

- ↑ https://www.thehomestud.com/how-to-make-wood-filler-with-sawdust/