This article was co-authored by Madison Boehm and by wikiHow staff writer, Amber Crain. Madison Boehm is a Business Advisor and the Co-Founder of Jaxson Maximus, a men’s salon and custom clothiers based in southern Florida. She specializes in business development, operations, and finance. Additionally, she has experience in the salon, clothing, and retail sectors. Madison holds a BBA in Entrepreneurship and Marketing from The University of Houston.

This article has been viewed 1,190 times.

Calculating a predetermined overhead rate (POR) is a great way for businesses to balance expenses with production costs and sales. If you want to learn how to use this tool for yourself, you’ve come to the right place! In this article, we’ll explain what a predetermined overhead rate is, what factors are used to determine it, and how to apply the formula. We’ll also provide several examples so you can see different ways POR can influence accounting and budgeting. If you’re ready to protect your profits and get a handle on business expenses, read on!

Things You Should Know

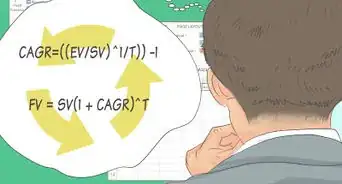

- A predetermined overhead rate is an estimated ratio of overhead costs calculated before a project or job begins.

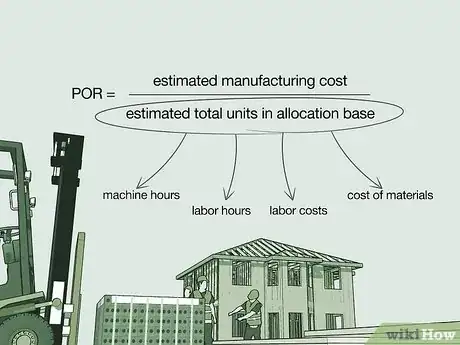

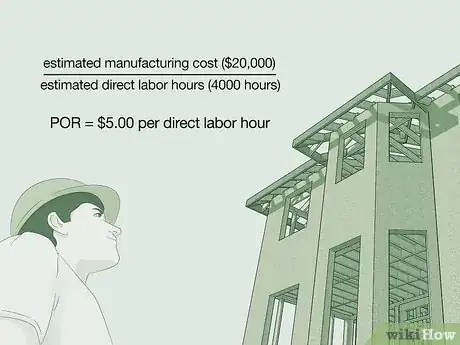

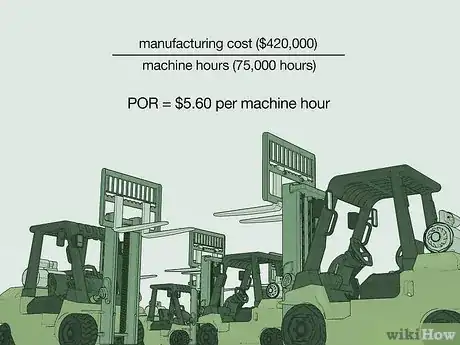

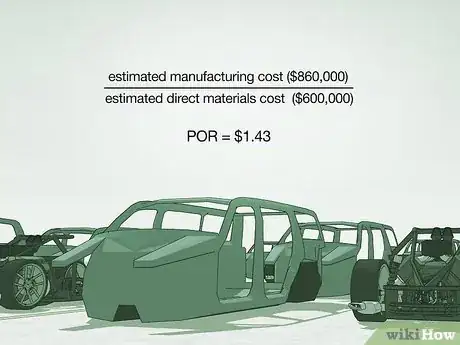

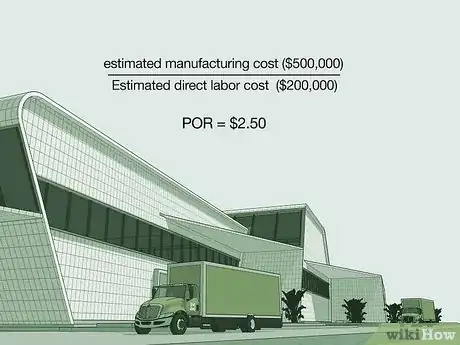

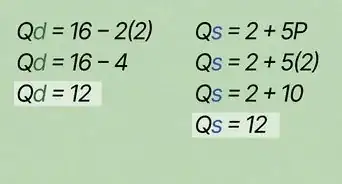

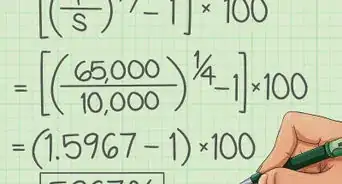

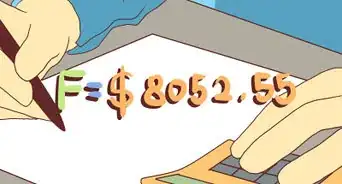

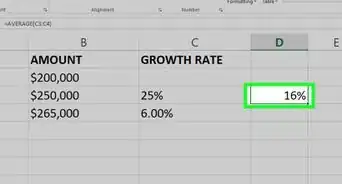

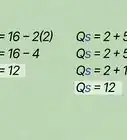

- To calculate predetermined overhead rate, use this formula: Estimated manufacturing cost / Estimated total units in allocation base.

- An allocation base is a cost accounting descriptor based on a common activity that affects overhead costs, like labor hours, machine hours, and cost of materials.

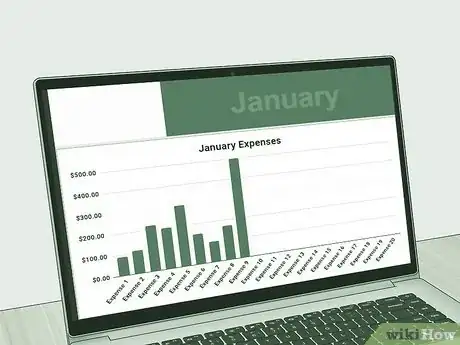

- Predetermined overhead rate is used to estimate future manufacturing costs so companies can plan, budget, and monitor costs.

Steps

Expert Interview

Thanks for reading our article! If you'd like to learn more about calculating rates, check out our in-depth interview with Madison Boehm.

References

- ↑ https://learn.financestrategists.com/explanation/cost-accounting/overhead-costing/predetermined-overhead-rate/

- ↑ https://thebusinessprofessor.com/en_US/accounting-taxation-and-reporting-managerial-amp-financial-accounting-amp-reporting/job-costing-assign-overhead-costs-explained

- ↑ https://manufacturing-software-blog.mrpeasy.com/manufacturing-overhead/

- ↑ https://fundsnetservices.com/predetermined-overhead-rate-formula

- ↑ https://fundsnetservices.com/predetermined-overhead-rate-formula

- ↑ https://learn.financestrategists.com/explanation/cost-accounting/overhead-costing/predetermined-overhead-rate/

- ↑ https://thebusinessprofessor.com/en_US/accounting-taxation-and-reporting-managerial-amp-financial-accounting-amp-reporting/job-costing-assign-overhead-costs-explained

- ↑ https://learn.financestrategists.com/explanation/cost-accounting/overhead-costing/predetermined-overhead-rate/

- ↑ https://learn.financestrategists.com/explanation/cost-accounting/overhead-costing/predetermined-overhead-rate/