This article was co-authored by Jon Depoian. Jon Depoian is a Skateboarding Instructor and the Owner of Intro2Skateboarding, an organization based in Orange County, California that provides professional private, home-school, after-school, birthday party, and summer camp skateboard lessons for beginners and experienced skateboarders alike. Jon has over 21 years of skateboarding experience and over 10 years of skateboard instruction experience. He also has extensive experience producing street skateboarding videos and skating competitions.

There are 8 references cited in this article, which can be found at the bottom of the page.

This article has been viewed 85,499 times.

Whether you want build a whole skateboard using a variety of brands or just need to replace a certain part, you can easily build your skateboard with a few tools, such as an allen wrench, socket wrench, or skateboard multitool. A skateboard should have a deck with grip tape, trucks, wheels, and bearings. It is relatively simple to customize your regular board, longboard, or penny board.

Steps

Assembling Your Parts and Tools

-

1Find a suitable workspace. Use a large, flat workspace where you can assemble your skateboard. You will be dealing with a lot of small parts like nuts, bolts, and washers.

- A large work table or open space on the floor works well. Just make sure that you have enough room to lay out all your parts and tools so you can easily find what you need.

- Keep your hardware in the original boxes or packaging until you need a particular piece to prevent losing anything.

- If you don't want to build your own board from absolute scratch, try buying a blank board from a local shop you can then implement your own design on.[1]

-

2Assemble the proper tools. You can use a regular set of tools, including a screwdriver, socket wrench, and Allen wrench/hex key. The easiest method is to use a multitool made for skateboards which include a variable size socket wrench, screwdriver, ratchet system, and Allen wrench.

- You will also need a razor blade to cut your grip tape, and a file.

- Some skateboard tools come with a razor and a file. If you don’t have one that does, use a straight edge razor or box cutter, and a metal file or sandpaper.

- Altogether, the deck will probably cost around $10, but the price of all the materials for the skateboard will be more around $100.[2]

Advertisement -

3Get your deck and grip tape. The deck is the curved wood (sometimes plastic or fiberglass) part of your board that you stand on. The grip tape is the black/gray (sometimes other colored) material that goes on top of your deck, to help you maneuver your board without slipping.[3]

- There are many brands and types of both decks and grip tapes. Some decks come with the grip tape already applied, if your deck doesn’t you will have to apply it yourself.

- Decks come in different widths and lengths. Most street skate decks are around 7.5” while park decks are around 8.5”. Decide if you plan on using your board more on the street or in a park. Then consider your stature. Shorter skaters with smaller feet don’t need as wide of a deck, while taller skaters could benefit from the extra room.

- Some grip tapes are less grippy than others. Grip tape is like sandpaper and made of different grains. If you are new to skating, you may want a medium grip and coarseness so that your feet can move easily without slipping.[4]

-

4Get your trucks, wheels, and bearings. Like decks and grip tape, you have plenty of options when it comes to your trucks, wheels, and bearings. The size, width, and height of these components will differ for everyone’s preferences.

- A good rule of thumb for trucks is to get ones that fit your board size. You don’t want trucks that are too wide for your board, or vice versa.[5]

- Wheels are typically made of polyurethane that allow you to grip, slide, and move fast. There are different options for the hardness of the wheel as well as the size. Cruising wheels, like the ones for longboards, are the biggest and softest. Small, harder wheels are better for street skating and tricks at the park as they allow for sliding. Then there are wheels that fit in between for versatile skating. Wheel sizes typically range between 49-75mm. Street wheels are typically around 50-55mm. Vert wheels are closer to 55-60mm, and longboard wheels are about 64-75mm.[6]

- Inside each wheel is a groove where the bearings go. The bearings allow the wheels to spin around the metal axle, which is fixed on a truck. Different bearings will also affect how fast and far you can go. The most common bearing size is the “608”. These bearings fit most wheels as the industry standard. Bearings come in steel and ceramic options. Ceramic bearings typically improve the performance of your board and movement but are more expensive. If you’re new to skateboarding, there are plenty of steel bearings that will be more than sufficient.[7]

- Note that trucks are often sold in singles. If you are purchasing trucks online, make sure you are getting a pair.

Putting the Grip Tape on Your Deck

-

1Lay your deck down on a flat surface. Putting grip tape on your deck isn’t very hard, but can take some practice to get it looking great. Start with your deck laying on a flat surface, right-side up.

- The nose and tail of your board should be pointing up with the flat part of your board resting on the surface.

- Your board may not lay completely flat due to its design.

- A good type of wood for your skateboard is hard Maple, because it's thin and durable.[8]

-

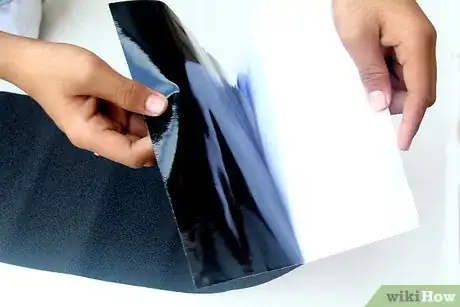

2Remove the backing of the grip tape. Your grip tape will come in a rectangular sheet that is longer and wider than your board. Lay it over the nose and tail of your board before peeling to make sure it covers the whole board. Then, peel off the back portion revealing the adhesive side.

- Be careful to touch as little of the grip tape as possible once you’ve peeled the paper away so you don’t accidentally get the tape stuck to anything and ruin it.

- Peel all of the back paper off at once.

-

3Place your grip tape down on your deck. Pinching the-the ends of tape between your forefinger and thumb, pull the tape taught. Find the nose and tail of your board with your middle fingers. You won’t be able to see the ends with the tape hovering over. Then, find the edge of your board and line the length of the grip tape along it so you can lay the tape down straight.

-

4Lay the tape down starting at the center of both the nose and tip, letting the tape fall naturally onto the top of your deck.[9]

- Once you have the tape placed on the top of the deck, take your palms and smooth out the grip tape. Make sure to press down hard and remove any air bubbles. Start in the middle of your board and move outwards towards the ends.

- It’s normal to have excess grip tape around your deck. Because your tape is a rectangle, and your board is more of an oval, you’ll have to remove the extra tape.

-

5Take your file and place it on the edge of your board, once your grip tape is laid down. This will create an outline of the deck under the grip tape.

- If you don’t have a file, use the edge of your Allen wrench.

-

6Cut off excess tape. Grab a straight razor or box cutter to cut away any extra grip tape. Start in the center of your deck and cut a small incision that’s perpendicular to your board. This incision will make it easier to cut away extra grip tape. Then cut around the entire circumference of your deck.

- The easiest way to get a smooth cut is to angle the razor slightly toward the top edge of the board, hold the outer portion of the tape and slide the razor toward you.

- Be very careful when doing this as the razor is very sharp and facing you.

- Take your time and move slowly.

-

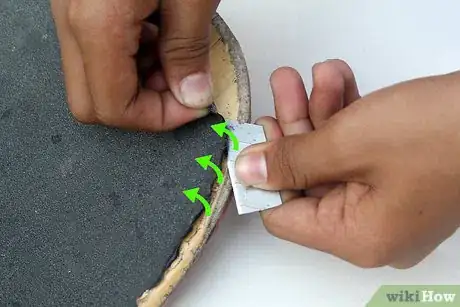

7Sand the grip tape edges. Take a portion of the tape that you cut away and fold it over on itself so the sticky part is on the inside. Then, like with sandpaper, run the tape around the edges to sand the edge of the tape down.

- Sanding your grip tape helps to prevent it from peeling up.

Attaching the Trucks and Wheels

-

1Insert your screws. Take your screwdriver or Allen wrench and punch holes through your grip tape. Hold your deck upright and locate the holes on the bottom of your board. Take your screwdriver and punch holes so that you can see where to place your screws. Then, insert your screws down through the top of your board.

- Some sets of trucks come with the proper size screws to attach the trucks to the board. Most of the time, however, you will have to purchase screws and nuts separately. Some sets will have two screws which are a different color. Use these screws to differentiate between the tip and tail of your board.

- When punching holes, keep the grip tape in place by holding it down with two fingers around the the hole.

-

2Attach the trucks. Now place the trucks onto your board. Hold the screws in place with one hand and align your trucks. The trucks attach to your deck at the baseplate. The baseplate is the flat square portion of your truck that has four holes for the screws. If placed correctly, the hanger, the “T” shaped part of your trucks will be facing down.[10]

- Take the nut that came with your screw and screw it on over the baseplate with your hand until you can’t tighten it anymore. Then use your socket wrench to tighten it further. Once your trucks are attached, hold the wrench in place over the bolt with one hand, and tighten the screws further with a screwdriver from the other side.

- Make sure your trucks are facing outward. The front of your trucks is the flat part of the hanger. It usually has the logo of the brand stamped on it. You can also tell which way is forward by the bushings. The bushings are the colored rubber parts under the kingpin, the top nut of your trucks.

- Both trucks should be facing outward. The flat sides should be facing away from each other with the bushing facing toward each other.

- If your trucks don’t come with hardware, you can buy hardware packs specifically designed for skate trucks.

- The heads of your screws should be flush with the grip tape when you are done, and you shouldn’t be able to jiggle the trucks at all.

-

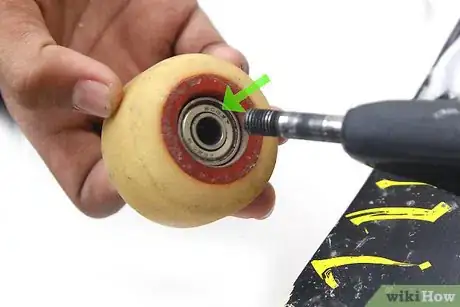

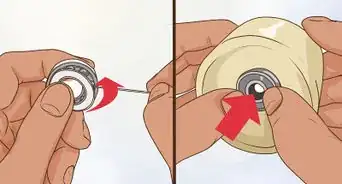

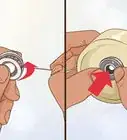

3Insert your bearings. Your bearings and wheels go on together. Remove the nut and washer from the axle of your truck first. Then grab a bearing. You’ll see a flat side and a ridged side on your bearings. You want the flat side facing out. Put one bearing on the axle, flat side facing up. Take your wheel and press it down over your bearing until you feel the bearing slide into the center of your wheel. Remove the wheel from your axle and slide a second bearing on. Repeat the process, flipping the wheel over.

- Place your board on your flat surface and stand the board on its edge for leverage.

- When putting the second bearing on, face your wheel out, with the graphics side exposed. This isn’t necessary, and some wheels may have graphics on both sides.

- If you have a bearing press, you can attach the bearings to the wheels without using your trucks.

-

4Attach your wheels. Place your washer down on top of your bearing, then add the nut. Screw the nut down as far as you can with your hands then grab your skate tool or wrench and continue to tighten the nut. If you have new wheels and bearings, tighten the nut down as far as you can. This will push the bearings down further into your wheel securing the bearing in place. Once everything is tightened all the way, loosen the nut a bit so the wheel can actually spin.

- Loosen the nut a few turns and spin your wheel, making sure that it can spin sufficiently.

- Grab the wheel with your fingers and pull on it. You should be able to feel and see it move or jiggle slightly.

-

5Make sure everything is tightened and tuned. With everything in place, place your board on the ground stand on it. Rock back and forth slightly and even skate around a bit. Test the tightness of your trucks and see how well the wheels spin while riding.

- If your trucks are too loose and the board feels wobbly, tighten each one. Grab your skate tool and rotate the nut on the kingpin clockwise about half a turn for each truck.

- If your trucks are too tight and you have trouble turning or carving, loosen each one. Turn the nut of your kingpin counterclockwise.

- Jiggle your trucks again to make sure each one is screwed in tightly to the deck.

- Adjust the tightness of your wheels. If you aren’t rolling as well as you should or feel resistance you may need to tighten your wheels further.

-

6Finished.

Removing Old Grip Tape

-

1Place your board on your flat surface.

-

2Get a hair dryer and heat up the edges for 3 to 5 minutes.

-

3Grab a razor blade and carefully insert it on a 45 degrees angle under the old grip tape.

-

4Stand on the board for leverage, once the edge of grip tape is pulled up.

-

5Peel it slowly, until you have removed the old grip tape.

-

6Apply the new grip tape. Your board is now ready.

Expert Q&A

Did you know you can get expert answers for this article?

Unlock expert answers by supporting wikiHow

-

QuestionHow much does it cost to build a skateboard?

Jon DepoianJon Depoian is a Skateboarding Instructor and the Owner of Intro2Skateboarding, an organization based in Orange County, California that provides professional private, home-school, after-school, birthday party, and summer camp skateboard lessons for beginners and experienced skateboarders alike. Jon has over 21 years of skateboarding experience and over 10 years of skateboard instruction experience. He also has extensive experience producing street skateboarding videos and skating competitions.

Jon DepoianJon Depoian is a Skateboarding Instructor and the Owner of Intro2Skateboarding, an organization based in Orange County, California that provides professional private, home-school, after-school, birthday party, and summer camp skateboard lessons for beginners and experienced skateboarders alike. Jon has over 21 years of skateboarding experience and over 10 years of skateboard instruction experience. He also has extensive experience producing street skateboarding videos and skating competitions.

Skateboarding Instructor

-

QuestionWhat kind of wood is good for skateboard decks?

Jon DepoianJon Depoian is a Skateboarding Instructor and the Owner of Intro2Skateboarding, an organization based in Orange County, California that provides professional private, home-school, after-school, birthday party, and summer camp skateboard lessons for beginners and experienced skateboarders alike. Jon has over 21 years of skateboarding experience and over 10 years of skateboard instruction experience. He also has extensive experience producing street skateboarding videos and skating competitions.

Jon DepoianJon Depoian is a Skateboarding Instructor and the Owner of Intro2Skateboarding, an organization based in Orange County, California that provides professional private, home-school, after-school, birthday party, and summer camp skateboard lessons for beginners and experienced skateboarders alike. Jon has over 21 years of skateboarding experience and over 10 years of skateboard instruction experience. He also has extensive experience producing street skateboarding videos and skating competitions.

Skateboarding Instructor

-

QuestionWhat do I do if I make a mistake with the griptape?

Community AnswerIf you have just made the mistake, you can usually easily pull the tape up slowly, and if you can't, you can use a heat gun, or in some cases a simple hair dryer on high heat.

Community AnswerIf you have just made the mistake, you can usually easily pull the tape up slowly, and if you can't, you can use a heat gun, or in some cases a simple hair dryer on high heat.

Things You'll Need

- Deck

- Grip tape

- Wheels

- Trucks

- Bearings

- Axle nuts

- Truck Bolts

References

- ↑ Jon Depoian. Skateboarding Instructor. Expert Interview. 5 June 2020.

- ↑ Jon Depoian. Skateboarding Instructor. Expert Interview. 5 June 2020.

- ↑ http://www.tactics.com/info/choosing-a-skateboard-deck

- ↑ https://www.youtube.com/watch?v=L0Z0R5z6aYU

- ↑ http://www.tactics.com/info/choosing-skateboard-trucks

- ↑ http://www.tactics.com/info/choosing-skateboard-wheels

- ↑ http://www.tactics.com/info/choosing-skateboard-bearings

- ↑ Jon Depoian. Skateboarding Instructor. Expert Interview. 5 June 2020.

- ↑ https://www.warehouseskateboards.com/help/How-to-Grip-a-Skateboard

About This Article

To build a skateboard, grab your skateboard multi-tool, sandpaper, and razor blade. Remove the backing from your grip tape and lay the grip tape over your deck so that it is fully covered. Then, carefully cut the excess tape off of your deck with your razor blade before sanding the edges to ensure that the grip tape is properly adhered. Using your multi-tool, cut holes in the top of your grip tape to attach your trucks. You will need to screw these in, making sure the trucks face outward. For more tips on which trucks, bearings, and wheels to choose, scroll down!