wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 18 people, some anonymous, worked to edit and improve it over time.

wikiHow marks an article as reader-approved once it receives enough positive feedback. In this case, 91% of readers who voted found the article helpful, earning it our reader-approved status.

This article has been viewed 626,046 times.

Learn more...

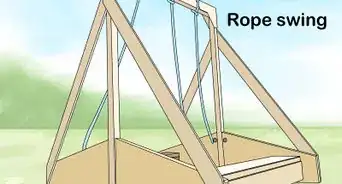

One of the most useful tools a carpenter can have in a construction project is a good pair of saw horses (or sawbucks, as they are sometimes called). You can build your own set if you have a circular saw, tape measure, an angle square and a hammer and nails.

Steps

-

1Get a couple of suitable boards for your project. 2X6 nominal southern yellow pine was used for the horses in the illustrations, and was ripped down, or split to make the finished product lighter in weight, but 2X4 (no ripping) using lodgepole or white pine, or spruce will also work. For horses that are to be left outdoors in the weather, it may be worthwhile to buy lumber that is treated to resist rot and insects.

-

2Set up a work table or other surface to measure and cut the lumber on. Since you are building the saw horses, it can be assumed you don't already have a set available, but if you do, of course use them.Advertisement

-

3Rip the lumber in half if you are using 2X6 boards and they do not have big knots or have to support a great deal of weight. This will reduce the total weight and amount of lumber required by half (compared to 2x6). For using full sized 2X4s, skip this step.

-

4Measure the length of the legs to a comfortable working height. For a typical 6 foot (1.8m) tall worker, 34-36 inches (.86-.91m) is about right, for shorter individuals, you may need to adjust the height. It is suggested you build your horses a bit tall, since the legs can be trimmed when they are complete to fit the user.

-

5Cut a bevel on the first leg when you cut it to length. For a good spread on the horse's legs, an angle of about 65 degrees from the square line, or 25 degrees from the board's edge should work nicely; those angles do and should total 90 degrees. You will want to note, you are cutting this bevel square to the narrow edge of your board, so you may find you need to mark both top and bottom, and recut through from the bottom to get all the way through the board. These cuts need to be flat (and straight), so they will fit against the top board flush and tightly.

-

6Cut the back or top board of your horse, which will be sawed square on both ends, about 42-48 inches (107-122cm) long. Make a mark an inch or so from each end, and draw a square line to determine where to attach the legs, on both sides.

-

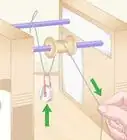

7Lay the back board on a flat surface, whether a work table, on a smooth floor, or even on the tailgate of a pickup truck. Position your first leg on the square mark made previously, and nail it so the bevel is set tightly against the edge of the top board. Blunting the point of your nails will decrease the likelihood the wood will split when it is nailed, and using an 8d (8 penny) nail for this will give sufficient holding power without passing through both pieces.

-

8Nail both legs on one side of the top board, then flip the assembly over. Nail the other two legs opposite to the first pair. You can use larger nails now, since if the points project through, they will go into the back of the first pair of legs and increase the strength of this joint.

-

9Stand your partially assembled horses upright, and measure down from the bottom of your top board about 8 inches (20cm), and using a short board, scribe it to be a horizontal spreader brace to fit between the legs. The angles on these braces should be roughly degrees 115 top and 65 bottom for total of 180 degrees, but scribing all of the braces in position will provide a better (more exact) fit. Use your scribed brace as a pattern to mark three additional pieces, making sure you have two for each Sawhorse.

- The 65 degree angle is called "25 from square" because you can find a 65 angle by marking "25 off from 90" using a tool called a 90 degree "rafter angle square," or "speed square" or similar instrument.

-

10Nail your braces in place, using two 12d nails in each end, going first through the leg, and into the end-grain of the brace.

~ Nail the braces on each pair of legs carefully, making sure they position the legs so the horse stands flat and straight on level ground.~ Nailing these braces out of position will mean the horse will wobble and be unsteady.~ Holding the horse upright and straight while nailing is worth the effort. -

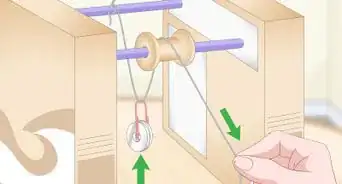

11Flip the horse back over on its top board, and prop it in place or have someone hold it. Cut another board about 18 inches (46cm) long, with a 45 degree angle on one end as the diagonal brace. Hold the angled end against the spreader brace and scribe the other end where it intersects the top board, then cut this mark. Use this piece for your pattern and for a pair of horses, cut 3 more.

-

12Nail these braces in place, with the end cut on a 45 degree angle butted into the spreader brace and nailed through from the brace into the end grain, and the scribed end to the underside of the top board. This will be nailed across the grain into the bottom of the top board, so use nails that are large enough to get a good bite, at least 12d, and blunt the ends to prevent the wood from splitting.

-

13Check your horses to make sure the legs are equal in length and fit the ground evenly. If not, you can trim the legs that are long, making sure the top board is parallel to the ground.

-

14Finished.

Community Q&A

-

QuestionWhat do I do if my saw blade is spinning in the wrong direction?

Community AnswerYou can tell if it's spinning in the wrong direction if it's difficult to cut, there's lots of smoke, or fire. To fix, switch off and disconnect the saw, use a vendor's wrench to remove blade nut, remove and flip over the blade, then tighten the blade nut.

Community AnswerYou can tell if it's spinning in the wrong direction if it's difficult to cut, there's lots of smoke, or fire. To fix, switch off and disconnect the saw, use a vendor's wrench to remove blade nut, remove and flip over the blade, then tighten the blade nut. -

QuestionHow do I get the angles?

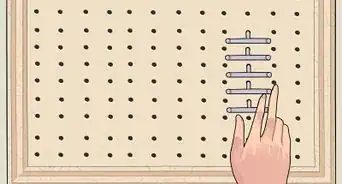

Community AnswerIf you're copying an existing saw-horse, use a sliding bevel tool, and a protractor -- from a table saw -- to capture and measure the angles. Or, if you use graph paper, you can quickly design your own, and measure the angles with an ordinary, draft-person's protractor.

Community AnswerIf you're copying an existing saw-horse, use a sliding bevel tool, and a protractor -- from a table saw -- to capture and measure the angles. Or, if you use graph paper, you can quickly design your own, and measure the angles with an ordinary, draft-person's protractor. -

QuestionHow do I get the correct angle?

Community AnswerWhatever the breadth of your timber, measure down 2.1 times this distance. For instance, if your nominal 2x4 is in fact 48mmx95mm, measure down 48mmx2.1 = 101mm, then draw your angle to the opposite corner. This is approximately 25 degrees (x 2.1445 to be precisely accurate).

Community AnswerWhatever the breadth of your timber, measure down 2.1 times this distance. For instance, if your nominal 2x4 is in fact 48mmx95mm, measure down 48mmx2.1 = 101mm, then draw your angle to the opposite corner. This is approximately 25 degrees (x 2.1445 to be precisely accurate).

Warnings

- Eye protection is recommended when sawing lumber and driving nails.⧼thumbs_response⧽

Things You'll Need

- A circular saw, tape measure, angle square (or speed-square), hammer, and nails.

-

Lumber of your preference. The horses in the illustrations required 2–10 foot (0.61–3.0 m) 2X6 boards, which were ripped to 2 3/4 inches wide, yielding 40 feet (12.2 m) of lumber.

- About 5- 8 foot (2.4 m) 2x4 boards would work (or 10- 42 to 48 inch boards will work).