This article was co-authored by Allen Lee and by wikiHow staff writer, Ali Garbacz. Allen Lee is a Home Improvement Specialist and the Owner of Honest Lee Handyman Services, a licensed and insured handyman business servicing Sacramento, California, and surrounding areas. Working with homeowners and businesses to get their small repairs done in a timely and efficient manner, Honest Lee Handyman Services provides gutter and dryer vent cleaning along with fixture, fence, drywall, and toilet repairs.

There are 7 references cited in this article, which can be found at the bottom of the page.

Aluminum and fiberglass are two of the main materials today’s ladders are made of, but which one will be best for you? Finding a ladder that will help you “reach” all of your project goals is important, and choosing a ladder made out of the right material is the first step in finding this match. We’ll walk you through the advantages of each ladder type as well as when each is best to use so you can feel confident when choosing a ladder for your next project.

Steps

Advantages of Aluminum Ladders

-

1Aluminum ladders are lightweight. Aluminum is a very lightweight material, so you’ll hardly have trouble carrying this ladder around while you get work done and can maneuver it along your house without the fear that you might accidentally bust through one of your windows. Aluminum is the lightest material in comparison to both fiberglass and wood.[1] X Research source

- The weight of a ladder will definitely vary by length and size, but aluminum ladders consistently weigh less than fiberglass ladders.[2] X Research source

- A 24 ft (7.3 m) extension ladder, one of the largest ladders, can weigh up to 170 lb (77.1 kg) when made of fiberglass, but only around 35 lb (15.9 kg) when made of aluminum.

-

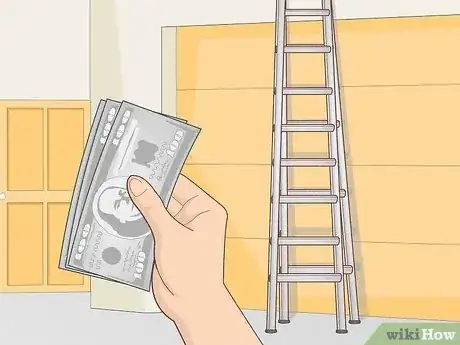

2They are extremely cost-effective. These ladders will be much cheaper than their fiberglass counterparts, and you’ll still be getting a stable and durable ladder despite the low cost.[3] X Research source

- For example, a 24 ft (7.3 m) aluminum ladder could cost around $280 already, but a fiberglass ladder can make that price shoot up to nearly $500.

Advertisement -

3Aluminum ladders are easier to maintain. While certain measures must be taken to ensure the longevity of other types of ladders, aluminum ladders do not require much care on your part. Of course, cleaning them after using them will help preserve them longer, but other than that they require no special treatment.[4] X Research source

- The average life expectancy of an aluminum ladder is around 20 years.[5] X Research source

- They also are not as susceptible to chipping and cracking like fiberglass ladders, whose coating can also be damaged when left out in the sun.

Advantages of Fiberglass Ladders

-

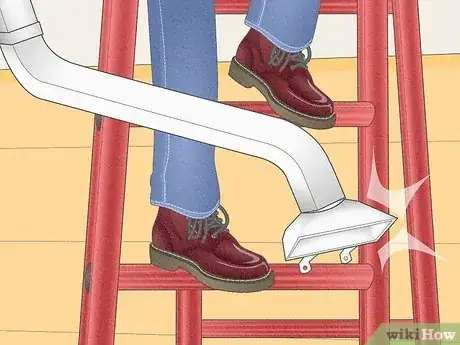

1They do not conduct electricity. Fiberglass is a plastic material reinforced by glass, neither of which conduct electricity. This makes it very safe to use when working with electricity or power supplies. Aluminum, on the other, is extremely conductive.[6] X Research source

-

2They can withstand heat. Unlike aluminum ladders, fiberglass ladders will not conduct heat as quickly and are thus safer to use when working near heat sources To avoid injury when working with machines or tools that may give off a lot of heat, a fiberglass ladder will be a much safer option.[7] X Research source

-

3Fiberglass ladders are some of the most durable ladders. While they are susceptible to chipping and cracking, fiberglass ladders are able to withstand these dents, scratches, and peeling for a longer period of time than other ladders. Given their heat-resistant properties, they also aren’t likely to bend and warp as easily as aluminum ladders.[8] X Research source

- Many fiberglass ladders have the highest durability rating of 1AA, meaning that they can carry a maximum of 375 lb (170.1 kg).[9] X Research source

Which one should you choose?

-

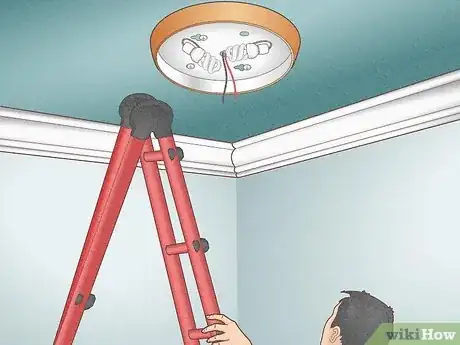

1Use fiberglass ladders for electrical work and simple at-home projects. Given how they are made of non-conducting material, a fiberglass ladder will be the safest option when working with electricity and power sources. Fiberglass ladders also offer more support and stability, with shorter step-ladders not differing much in weight from aluminum ladders. So you might consider trading in your aluminum ladder for a more stable fiberglass one when doing projects that don’t require much height.[10] X Research source

- Never use an aluminum ladder when dealing with power lines or electrical wiring, as aluminum is extremely conductive and can lead to serious injury.[11] X Research source

-

2Aluminum ladders are best for high-up projects and are durable yet cheap. When you need to use something like an extension ladder, it’ll be much easier to carry around and maneuver a ladder that’s made of aluminum. You also won’t have to break the bank to get one of these, as they’re very cost-effective while not sacrificing durability or stability.[12] X Research source

You Might Also Like

References

- ↑ https://www.americanladderinstitute.org/page/Ladders101

- ↑ https://laddergeek.com/how-much-does-a-ladder-weigh/

- ↑ https://laddergeek.com/fiberglass-vs-aluminum-ladder/

- ↑ https://www.lni.wa.gov/safety-health/safety-topics/topics/ladder-safety

- ↑ https://laddergeek.com/how-long-do-aluminum-ladders-last/

- ↑ https://woodthrive.com/wood-aluminum-fibreglass-ladder/

- ↑ https://laddergeek.com/fiberglass-vs-aluminum-ladder/

- ↑ https://laddergeek.com/fiberglass-vs-aluminum-ladder/

- ↑ https://www.americanladderinstitute.org/page/Ladders101

About This Article